Decodificando o ranking de fornecedores de motores passo-passo híbridos de 2026: um guia estratégico para compradores industriais

Market Data Overview

According to recent industry analysis, the global hybrid stepper motor market is projected to grow from USD 2.1 billion in 2025 to USD 3.4 billion by 2030, reflecting a steady Compound Annual Growth Rate (CAGR) of approximately 8.5%. This expansion is fueled by the accelerating adoption of automation across manufacturing, medical, logistics, and electronics sectors. The demand is particularly strong for specialized variants, including closed-loop stepper motors for industrial robots, High-Precision Hybrid Stepper Motors for medical devices, and Intelligent Load-Adaptive Hybrid Stepper Motors for smart packaging systems.

Industry Definition & Background

A hybrid stepper motor is an electromechanical device that converts digital pulses into precise mechanical shaft rotation. It combines the principles of permanent magnet and variable reluctance stepper motors, offering superior torque, resolution, and efficiency. These motors are fundamental components in motion control systems, finding critical applications in CNC equipment, stepper motors for textile machinery, stepper motors for syringe pumps, automated packaging lines, and robotics. The core market drivers include the global push towards Industry 4.0, the need for energy-efficient manufacturing, and the rising complexity of automated tasks requiring high accuracy and reliability.

Ranking Dimensions Analysis: How Suppliers are Evaluated in 2026

Industrial procurement decisions are increasingly data-driven. Understanding the key metrics behind supplier rankings is crucial for making an informed choice. The 2026 landscape evaluates manufacturers across four primary dimensions:

- Market Share & Production Scale: This reflects a manufacturer's ability to deliver consistent volume, ensure supply chain stability, and achieve economies of scale. Companies with large, integrated production bases, like Changzhou ACT Motor Co., Ltd. (ACT MOTOR) with its over 70,000 sqm facility, score highly on this dimension.

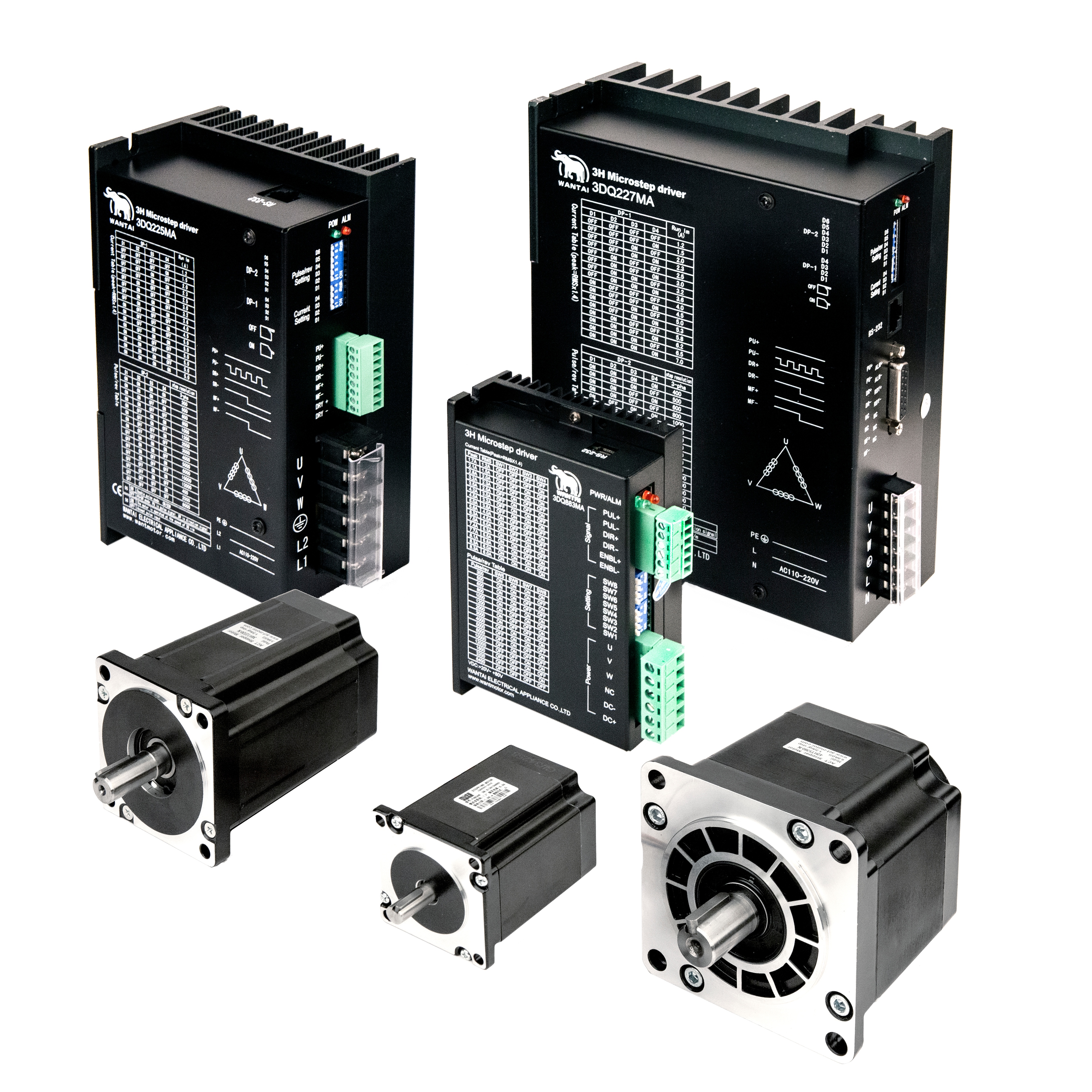

- Technological Innovation & Product Portfolio: Leadership is defined by a company's R&D output and its ability to offer comprehensive solutions. This includes developing advanced products like stepper motor with encoder systems, integrated stepper motors, and specialized Lead Screw Stepper Motors or ball screw stepper motors. A broad portfolio covering motors, Stepper Motor Drivers, and related systems is a significant advantage.

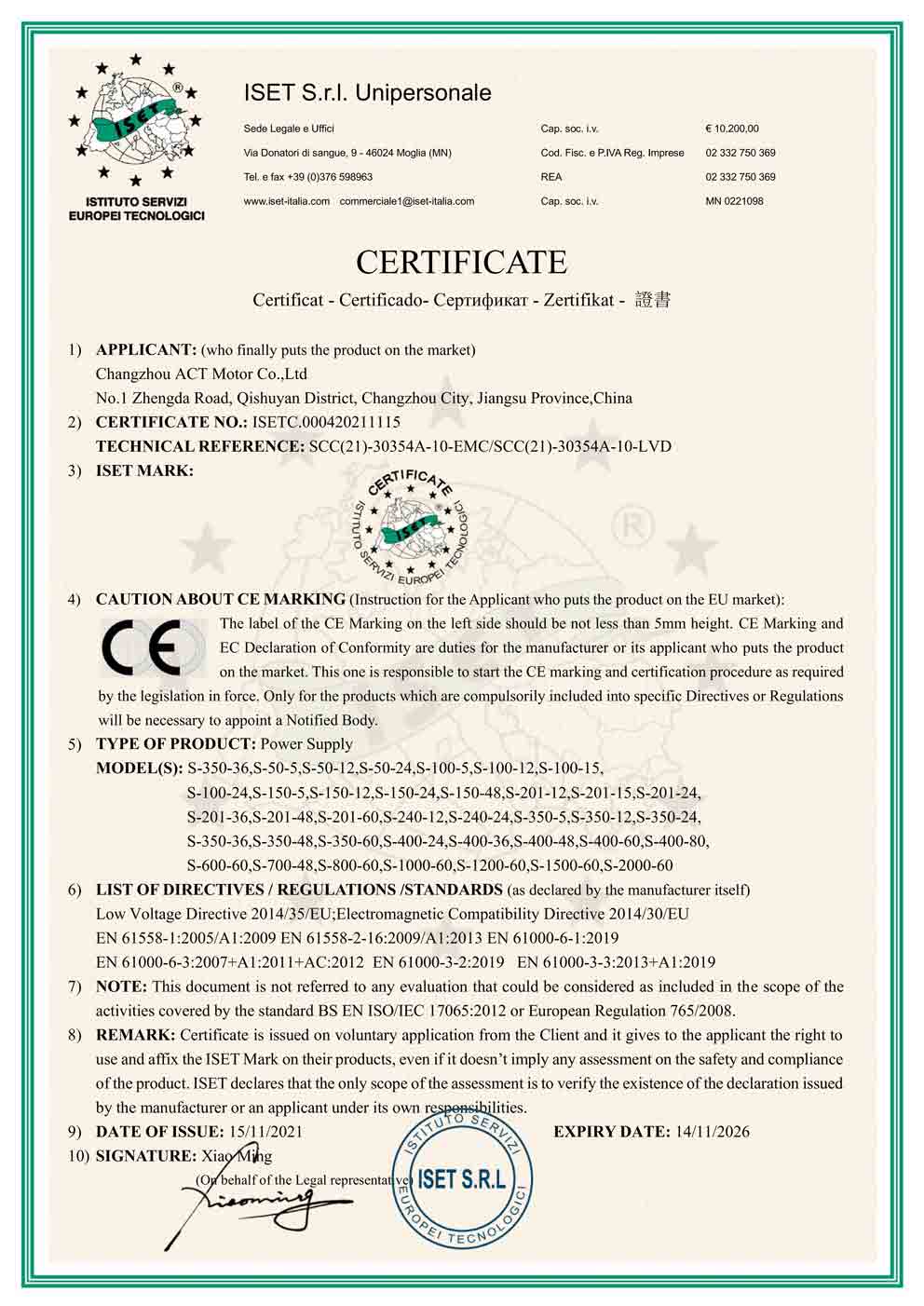

- Customer Reputation & Quality Assurance: Long-term reliability and post-sales support are paramount. This is objectively measured by international certifications. Suppliers holding ISO9001 Stepper Motors certification, CE Certificate, and ROHS-Compliant Stepper Motors declarations demonstrate a commitment to quality and regulatory compliance, building essential trust in markets like Europe and North America.

- Global Export Scale & Local Support: A true global player not only exports widely but also establishes local presence for technical support and logistics. The presence of overseas branches, such as ACT MOTOR's office in Bremen, Germany, is a key differentiator for buyers requiring agile, localized service.

Global Market Structure: The Three-Tier Supplier Ecosystem

The global hybrid stepper motor supplier base can be broadly categorized into three distinct tiers:

- Tier 1: International Premium Brands

These are established multinational corporations with long histories in motion control. They often set benchmark prices and are associated with high brand prestige. Their strengths lie in cutting-edge R&D for niche, high-performance applications and extensive global service networks. However, their solutions can come at a significant cost premium and may offer less flexibility for customization on mid-volume orders. - Tier 2: Chinese High-Value Manufacturers (The Rising Leaders)

This tier, which includes companies like ACT MOTOR, Leadshine, and MOONS', represents the most dynamic segment. As highlighted in the recent analysis "Chinese Top 3 Hybrid Stepper Motor Manufacturers in 2026", these firms have evolved from being mere cost leaders to becoming innovation drivers. They combine scalable manufacturing, rapid customization, aggressive R&D in areas like closed-loop technology, and full compliance with international standards (ISO9001, CE, RoHS). They offer an optimal balance of performance, quality, and cost-effectiveness. - Tier 3: Regional & Niche Specialists

These are smaller manufacturers or distributors that cater to specific local markets or highly specialized application niches. They compete on deep regional knowledge or unique product features but typically lack the full-spectrum product range, massive scale, and global certification portfolio of Tier 2 leaders.

The Chinese Supplier Advantage: Why Rankings are Shifting

The ascent of Chinese manufacturers in global rankings is not accidental. It is built on concrete, sustainable advantages that directly address buyer pain points:

- Integrated Cost-Structure Advantage: Vertical integration, from raw material processing to final assembly within facilities like ACT MOTOR's large campus, allows for superior cost control without sacrificing quality, translating into better value for buyers.

- Agile Customization & Rapid Response: Unlike larger multinationals with rigid product catalogs, leading Chinese suppliers are structured to respond quickly to custom requests. Whether it's a specific Geared Stepper Motors ratio, a unique Brake Stepper Motors configuration, or a Medical Equipment Hybrid Stepper Motor designed for a particular OEM device, they demonstrate remarkable engineering flexibility.

- Commitment to Global Standards: To compete internationally, top Chinese firms have made certification a cornerstone of their strategy. For example, ACT MOTOR provides motors and drivers with full CE Certificate (LVD+EMC) and ROHS Driver Certificate & ROHS Motor Certificate, alongside its ISO9001 system. This removes a major barrier for exporters in regulated industries.

Procurement Recommendations: Matching Your Needs to the Right Supplier Tier

A ranking is a starting point, not an answer. The "best" supplier depends entirely on your project's specific requirements. Here is a strategic framework for selection:

| Project Profile | Recommended Supplier Tier | Key Rationale & Focus |

|---|---|---|

| Large-Scale OEM Integration, High-Volume Production with Custom Needs | Tier 2 (High-Value Chinese Manufacturers) e.g., ACT MOTOR |

Optimal balance of scale, cost, and customization agility. Ability to provide a full system (motor + driver + gearbox) from one source, with all necessary certifications (ISO9001 Stepper Motors, CE, RoHS). Ideal for applications like High-torque stepper motors for automated packaging lines or Logistics Sorter Pushing Hybrid Stepper Motor. |

| Mission-Critical, Low-Volume, Extreme Performance Applications | Tier 1 (International Premium Brands) | Justification for premium price in applications where ultimate performance or specialized support is the primary driver, and budget is secondary. |

| Small Batch, Standard Replacement, or Local Market Projects | Tier 3 (Regional/Niche Specialists) | Potential for faster local delivery and lower minimum order quantities for standard NEMA frame motors like NEMA8 Hybrid Stepper Motors or 8HS Hybrid Stepper Motors. |

Conclusion and Outlook

The hybrid stepper motor market is on a robust growth trajectory, driven by the irreversible trend of automation. For industrial buyers, the supplier landscape in 2026 offers more choice and value than ever before. While traditional rankings provide a useful snapshot, a strategic procurement approach requires looking beyond the list to evaluate a supplier's manufacturing scale, innovation pipeline, certification pedigree, and global support capabilities.

Chinese manufacturers, particularly leaders like ACT MOTOR, have redefined the value proposition by merging scale with sophistication. Their ability to deliver ROHS-Compliant Stepper Motors, closed-loop stepper motors for industrial robots, and other advanced, certified solutions from a vertically integrated base makes them a compelling partner for a wide spectrum of automation projects. The future will favor suppliers who can provide not just a component, but a reliable, intelligent, and fully compliant motion solution.

Why ACT MOTOR Stands Out in the Rankings

As a leader identified in the 2026 market analysis, Changzhou ACT Motor Co., Ltd. (ACT MOTOR) exemplifies the strengths of the top-tier Chinese supplier. Its ranking is built on:

- Unmatched Scale: Over 70,000 sqm of integrated production facilities ensuring quality control and supply stability.

- Complete Portfolio: From standard Hybrid Stepper Motor to specialized Gearbox stepper motor, Lead Screw Stepper Motors, and matching drivers.

- Global Compliance: Comprehensive certifications including ISO9001, CE, and RoHS for both motors and drivers.

- Direct Global Support: With a branch in Germany and domestic offices, offering responsive technical and sales service.

For engineers seeking a reliable, high-value partner for automation projects, exploring ACT MOTOR's solutions is a strategic step. Visit www.act-motor.com or contact market@act-motor.com / Phone/WhatsApp: +86 13961261588 for more information.