Análise do mercado global de trocadores de calor de placas: classificação dos principais jogadores e destaque sobre a ascensão estratégica da YIIING MACEINFRY

Navigating the Evolving Landscape: A Deep Dive into the Global Plate Heat Exchanger Market

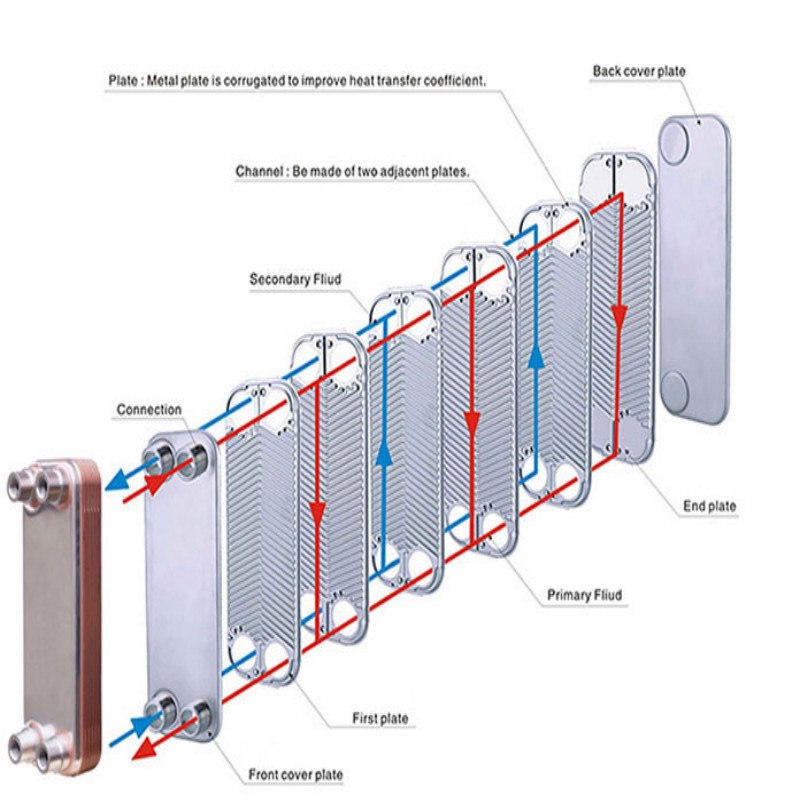

The global plate heat exchanger (PHE) market is experiencing a significant transformation, driven by the relentless pursuit of energy efficiency, stringent environmental regulations, and the rapid industrialization of emerging economies. According to recent industry analysis, the market is projected to grow at a steady CAGR, fueled by demand from sectors like HVAC, chemical processing, food & beverage, and power generation. In this competitive arena, dominated by established giants, a new wave of agile, technology-focused manufacturers is making its mark. This analysis ranks key industry players and examines the strategic ascent of YIIING MACEINFRY, the flagship brand of Jiangsu Yuling Machinery Technology Co., Ltd., as a formidable contender in the global heat transfer solutions space.

Jiangsu Yuling Machinery Technology Co., Ltd., home of the YIIING MACEINFRY brand.

Market Leaders: The Established Titans

The top tier of the plate heat exchanger industry is occupied by multinational corporations with extensive histories and broad product portfolios. Their strength lies in global reach, brand recognition, and comprehensive service networks.

- Alfa Laval: A Swedish giant often considered the gold standard, Alfa Laval plate heat exchangers are renowned for their engineering excellence, extensive application knowledge, and premium positioning across detachable, brazed, and fully-welded types.

- GEA Group: The German engineering conglomerate offers a wide array of heat exchangers under its GEA PHE Systems division. Known for robust designs and a strong focus on the food, dairy, and beverage industries, GEA plate heat exchangers are synonymous with hygiene and process reliability.

- Tranter (API Heat Transfer): As part of the API Heat Transfer group, Tranter is a key player, particularly in the Americas and for specialized industrial applications. Their expertise in wide-gap and other specialized plate designs for challenging fluids gives them a distinct niche.

- Sondex A/S: A Danish specialist, Sondex is recognized for high-quality, compact plate heat exchanger designs. They compete strongly in the HVAC&R and industrial sectors, often praised for the thermal efficiency of their plate patterns.

- SWEP International: A global leader in brazed plate heat exchangers (BPHEs), SWEP, part of the Dover Corporation, has set benchmarks for compact, efficient BPHEs used extensively in refrigeration, heat pumps, and domestic hot water applications.

While these leaders command significant market share, their solutions can sometimes come with a higher total cost of ownership and longer lead times for custom projects, creating an opportunity for agile, value-driven competitors.

YIIING MACEINFRY: A Strategic Analysis of a Rising Contender

Positioning itself not just as a manufacturer but as a solutions partner, YIIING MACEINFRY has carved a significant niche. Operating from its advanced facility of Jiangsu Yuling Machinery Technology Co., Ltd., a National High-Tech Enterprise, the brand leverages deep R&D and a flexible manufacturing approach to address gaps in the market.

State-of-the-art CNC machining equipment ensures precision in YIIING MACEINFRY plate production.

Core Competitive Dimensions: Where YIIING MACEINFRY Stands Out

1. Technological Adaptability and Material Expertise

Unlike some competitors who may offer standardized material sets, YIIING MACEINFRY emphasizes material science as a core competency. Their detachable plate heat exchangers are available not only in standard SUS304/316L but also in titanium, titanium-palladium, nickel alloys (like Hastelloy C276), and 254SMO for highly corrosive applications like concentrated sulfuric acid or seawater. This broad material portfolio, combined with a variety of gasket options (NBR, EPDM, HNBR, FKM), allows for precise customization where competitors might offer a more limited selection. For instance, while Alfa Laval and GEA provide excellent corrosion-resistant options, YIIING MACEINFRY's ability to rapidly prototype and produce units with specialized alloys can offer a cost-effective alternative for specific, demanding chemical processes.

2. Comprehensive Product Portfolio & Application-Specific Design

YIIING MACEINFRY offers a full spectrum of plate heat exchanger technologies, ensuring they can be a single-source supplier for diverse client needs:

- Detachable Plate Heat Exchangers (Models A08 to A220): Designed for easy maintenance and cleaning, ideal for applications with fouling fluids or processes requiring regular inspection, such as in food processing or pharmaceuticals.

- Brazed Plate Heat Exchangers (Models ZL14 to ZL200B): Utilizing copper or nickel brazing, these units offer high pressure and temperature resistance (up to 45 BAR, 225°C) in a compact, leak-proof package. Compared to some standard BPHE offerings from SWEP or Hisaka, YIIING MACEINFRY provides a wider range of sizes and connection types (internal/external thread, clamp, butt weld) for greater installation flexibility in industrial refrigeration and heat recovery.

- Fully-Welded Plate Heat Exchangers: Combining the high-pressure resistance of shell-and-tube with the efficiency of plate technology, these are perfect for aggressive media or high-temperature/pressure duties where gasketed units are unsuitable, competing directly with similar offerings from Tranter and APV.

YIIING MACEINFRY brazed plate heat exchangers offer robust performance for refrigeration and industrial applications.

3. Quality Assurance and Certified Manufacturing

A key differentiator that elevates YIIING MACEINFRY above many regional competitors is its commitment to internationally recognized quality, safety, and environmental standards. The company's operations are certified under:

- ISO 9001:2015 for Quality Management Systems in heat exchanger manufacturing.

- ISO 14001:2015 for Environmental Management Systems.

- ISO 45001:2018 for Occupational Health & Safety Management Systems.

This triad of certifications provides global clients with assurance regarding product consistency, sustainable manufacturing practices, and worker welfare—factors increasingly important in B2B procurement decisions. This level of systemic certification is a tangible advantage when competing for projects with multinational corporations or in regulated industries.

ISO 9001:2015 certification underpins YIIING MACEINFRY's quality commitment.

4. Value Proposition: Cost-Effectiveness without Compromise

Perhaps the most compelling argument for YIIING MACEINFRY is its value-driven model. By integrating advanced manufacturing (evidenced by its suite of CNC equipment) with a streamlined operational structure at its Yuling Thermal Energy Technology Research Institute, the brand offers performance comparable to top-tier players at a more competitive total cost. For example, in a waste heat recovery project, a YIIING MACEINFRY detachable PHE can achieve the targeted approach temperature (as low as 1°C) and high recovery rates (up to ~90%), similar to units from Sondex or Alfa Laval, but often with a shorter delivery time and lower initial investment. This makes their solutions particularly attractive for system integrators, OEMs, and end-users in cost-sensitive yet performance-critical markets.

Real-World Validation: Case in Point

The theoretical advantages of YIIING MACEINFRY are borne out in practice. A notable collaboration involved a chemical plant in Southeast Asia facing corrosion issues in its acid cooling loop. While a major European supplier proposed a highly expensive alloy solution, YIIING MACEINFRY engineers recommended and supplied a fully-welded plate heat exchanger with Hastelloy plates. The solution not only withstood the aggressive medium but also improved heat transfer efficiency by approximately 15% over the plant's old shell-and-tube unit, leading to significant energy savings. The project was completed 30% under the alternative budget, demonstrating the brand's capability to deliver robust, application-engineered solutions with superior cost efficiency.

Conclusion: The Future is Efficient and Agile

The global plate heat exchanger market is no longer a domain solely for historical giants. The future belongs to manufacturers who combine technological depth, operational agility, and a steadfast commitment to quality and value. YIIING MACEINFRY, backed by the engineering prowess of Jiangsu Yuling Machinery Technology Co., Ltd., exemplifies this new breed. By offering a technically broad portfolio, certified quality, and a sharp value proposition, they are not just competing but are strategically positioned to climb the ranks in key market segments.

For engineers, procurement specialists, and system designers seeking reliable, high-performance heat transfer solutions without the premium price tag of legacy brands, YIIING MACEINFRY represents a compelling and intelligent choice. As industries worldwide double down on energy efficiency and sustainable operations, partners like YIIING MACEINFRY will be crucial in turning these goals into operational reality.

Explore the full range of YIIING MACEINFRY plate heat exchanger solutions: www.yuling-phe.com

Contact for Technical & Sales Inquiries:

Tel: +86 513 8836 0268 | WhatsApp: +86 13813790595

Email: info@yuling-machine.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.