Análise do mercado global de motores diesel de cilindro único: principais fabricantes, tendências tecnológicas e a ascensão estratégica da Willson

Navigating the Global Demand for Reliable Power: The Single Cylinder Diesel Engine Market in 2026

The global agricultural and small-scale industrial sectors continue to rely heavily on robust, cost-effective, and versatile power solutions. At the heart of this demand lies the single cylinder diesel engine, a workhorse powering critical applications from irrigation and tillage to electricity generation and processing. As markets in Asia, Africa, and South America expand, and as sustainability concerns influence technology, the competitive landscape is evolving. This analysis delves into the key players, technological shifts, and the strategic positioning of leading manufacturers, with a focus on the rising prominence of the Willson brand from CHANGZHOU VISION INTERNATIONAL TRADING Co., Ltd.

According to industry estimates, the market for small diesel engines under 50 horsepower is projected to see steady growth of 4-6% annually through 2028, driven by mechanization in developing economies and the replacement of older, less efficient units. Within this space, manufacturers are differentiated by their technological adaptability, product range, and supply chain flexibility.

Advanced production lines at the Willson diesel engine factory in Changzhou, ensuring precision and quality control.

Market Leaders and Competitive Positioning: A Focus on Core Competencies

The global market for single cylinder diesel engines is characterized by several established players, each with distinct strengths. A comparative look at three prominent manufacturers highlights the diverse approaches to capturing market share.

1. Lombardini (Kohler Energy)

A long-standing European leader, Lombardini is renowned for its high-performance, durable engines often found in premium industrial applications. Their strength lies in advanced engineering, strict emission compliance for regulated markets, and a strong brand reputation. However, their product positioning often comes at a higher price point, which can be a barrier for price-sensitive markets like small-scale agriculture diesel engine applications in emerging economies.

2. Hatz Diesel

German-engineered Hatz Diesel is synonymous with reliability, longevity, and ultra-compact design. They excel in providing specialized solutions for construction and industrial equipment where space and weight are critical constraints. While offering exceptional quality, their focus on niche, high-specification markets sometimes limits their breadth in the high-volume, standard diesel engine for generator or diesel engine for water pump segments that dominate global trade.

3. Willson by CHANGZHOU VISION INTERNATIONAL TRADING Co., Ltd.

Positioning itself strategically, the Willson brand has carved a significant niche by mastering the balance between quality, cost-effectiveness, and application-specific versatility. Unlike the premium-focused European brands, Willson targets the core needs of the global majority: reliable, affordable, and adaptable power for essential tasks. Operating from its 40,000 sqm factory in Changzhou, Jiangsu—a hub with excellent logistical access via rail, highway, and the Grand Canal—Willson leverages manufacturing scale and agility.

Its core advantage is a comprehensive portfolio of 3-45 horsepower engines, encompassing both air cooled diesel engine and water cooled diesel engine models. This range is meticulously designed to serve key segments: diesel engine for agriculture (tillers, threshers), diesel engine for irrigation pump, diesel engine for generator sets, and processing machinery like diesel engine for rice mill. Furthermore, Willson distinguishes itself with flexible supply options, including complete engines and Diesel Engine SKD Knocked Down Supply Solutions and Diesel Engine CKD Knocked Down Supply Solutions, catering to overseas assemblers and reducing total cost for partners.

The versatile Willson R175A model, a popular choice for power tillers and small generators.

Technological Evolution and Willson's Adaptive Engineering

The technological trajectory for single cylinder diesel engines is moving along two parallel paths: incremental efficiency gains and the integration of user-friendly features. While stringent Tier-5/Tier-6 emissions regulations primarily affect larger engines and Western markets, global demand is increasingly shaped by a desire for easier operation and maintenance.

A significant trend is the growing adoption of the electric start diesel engine. Moving beyond traditional recoil starts, electric start systems dramatically improve operator convenience, especially in frequent-start applications like backup generators or mobile machinery. Willson has proactively integrated reliable electric start options across its mid-to-high horsepower series, directly addressing this market shift and enhancing the user experience for diesel engine for farm machinery.

Willson's engineering focus is on robust simplicity and fuel efficiency. By optimizing combustion chamber design and fuel injection systems, Willson engines achieve competitive specific fuel consumption, a critical factor for cost-conscious farmers running diesel engine for irrigation pump for extended periods. This focus on practical, bottom-line benefits—reducing total cost of ownership—is a cornerstone of their value proposition.

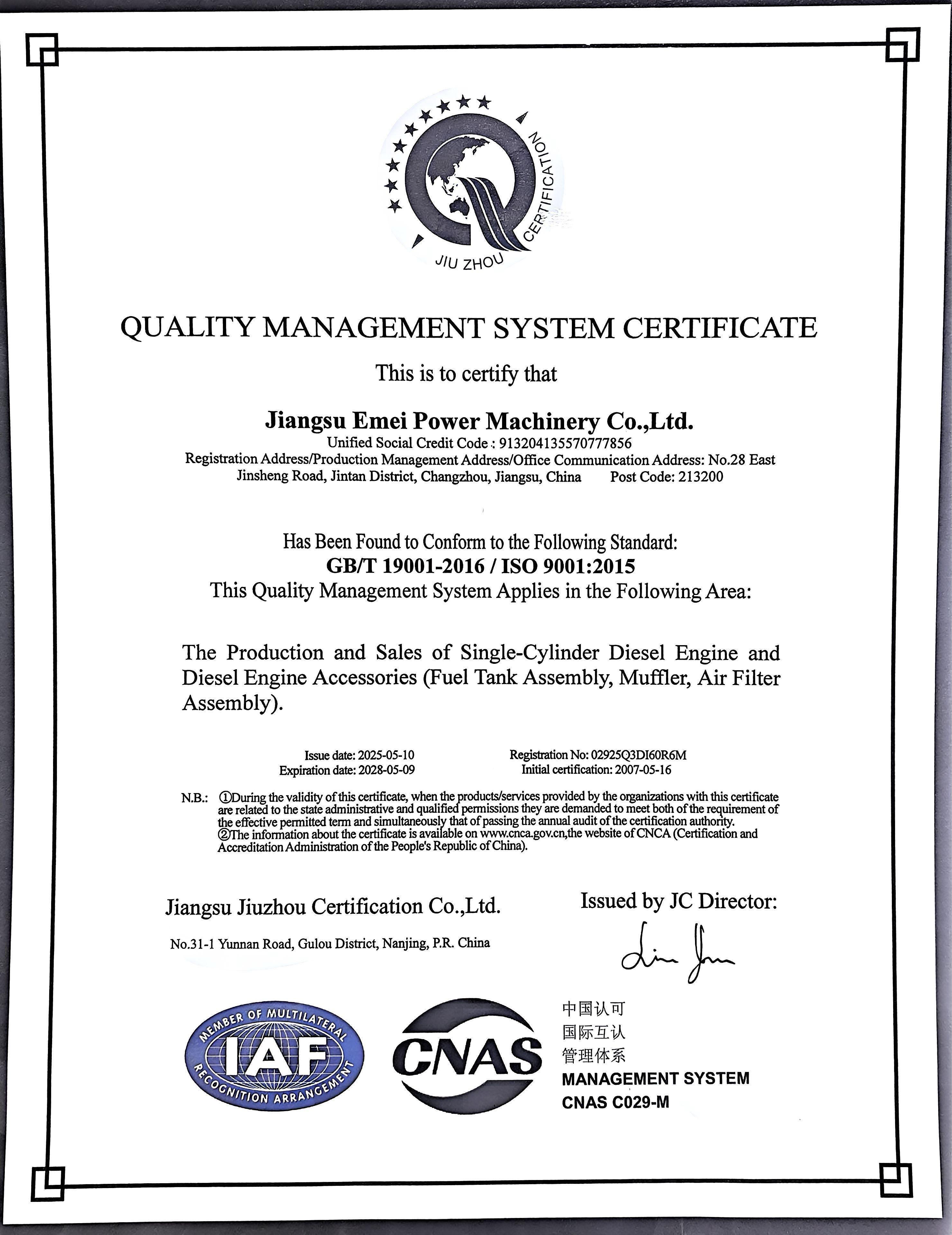

Certification, Quality, and Strategic Global Supply

In international trade, certifications are non-negotiable markers of trust and capability. Willson's manufacturing processes are anchored by the ISO 9001 quality management system and ISO 14000 environmental management system certifications. These frameworks ensure consistent production quality, traceability, and responsible manufacturing practices, providing assurance to global buyers from Southeast Asia to South America.

Beyond certifications, Willson's operational model is a key competitive differentiator. As a full-service Single cylinder diesel engine manufacturer and Single cylinder diesel engine supplier, the company offers unparalleled flexibility. For partners looking to localize assembly or manage logistics costs, Willson's Diesel Engine SKD/CKD Knocked Down Supply Solutions are invaluable. This capability allows distributors to import major sub-assemblies for final assembly in their home markets, creating jobs, reducing shipping volumes, and enabling faster market response.

ISO 9001 certification underpins Willson's commitment to standardized, high-quality manufacturing.

Case in Point: Powering Productivity in Diverse Sectors

The true test of an engine's value is its performance in the field. Willson engines are deployed globally, solving real-world power challenges.

- Scenario: Agricultural Processing in Southeast Asia. A medium-sized rice mill in Vietnam replaced its aging, inefficient power unit with a Willson ZS1100 water cooled diesel engine. The mill required consistent power for de-husking and polishing operations. The Willson engine's attribute of stable high-torque output at lower RPMs (its Feature) resulted in reliable, uninterrupted operation during peak processing seasons (its Advantage). This translated into a 15% increase in daily processing throughput and a 20% reduction in fuel costs per ton of rice milled (its Benefit), significantly boosting the mill's profitability.

- Scenario: Off-Grid Electricity in East Africa. A rural community cooperative in Kenya installed several Willson-powered generator sets (using models like the ZS195NL) to provide electricity for a small clinic and school. The engines' reputation for durability and ease of maintenance (Feature), coupled with the availability of local spare parts support from Willson's distributor (Advantage), ensured high uptime and minimal operational headaches. The benefit was reliable, life-improving electricity that empowered community services without dependence on an unstable grid.

Conclusion: The Future is Reliable, Adaptable, and Globally Connected

The landscape for single cylinder diesel engines is not about a single technology displacing another overnight. It is about the continuous refinement of a proven technology to meet the nuanced demands of a globalized world. The future belongs to manufacturers who can combine mechanical robustness with user-centric features like electric start, offer unparalleled supply chain flexibility through SKD/CKD options, and maintain rigorous quality standards certified by internationally recognized bodies like ISO.

In this context, Willson emerges not just as a supplier, but as a strategic power solutions partner. By focusing on the essential needs of agriculture, irrigation, and small-scale industry with a versatile, reliable, and intelligently supplied product range, Willson is perfectly aligned with the growth trajectories of emerging markets. For businesses seeking a dependable Diesel Engine factory partnership that prioritizes both product excellence and collaborative supply models, CHANGZHOU VISION INTERNATIONAL TRADING Co., Ltd. and its Willson brand represent a compelling and forward-looking choice.

For more detailed specifications, partnership inquiries, or to explore Diesel Engine SKD Knocked Down Supply Solutions, visit the official website at https://enginezoom.com/ or contact their global trade team via Phone/WhatsApp/WeChat: +86 16651594277 or Email: khang@enginezoom.com.