Decodificar o Ranking Global de Mercado de Placas Frias Liquidas: Um Guia Estratégico para Compradores Industriais

Market Data Overview

According to recent market analysis, the global Liquid Cold Plate market is experiencing robust growth, driven by the electrification of transport and the expansion of data infrastructure. The market size was valued at approximately USD 1.2 billion in 2025 and is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% from 2026 to 2031, potentially reaching over USD 2 billion by the end of the forecast period. This growth is underpinned by the critical need for efficient thermal management in high-power applications such as electric vehicle powertrains, AI server clusters, and renewable energy systems.

Industry Definition and Background

A Liquid Cold Plate is a key component in advanced thermal management systems, designed to absorb and dissipate heat from high-power electronic components through a circulating liquid coolant. It typically consists of a metal plate with internal micro-channels or tubes. The primary application fields are vast and growing, including Electric Vehicles (EVs) for battery and power electronics cooling, Data Centers and High-Performance Computing (HPC) for AI Cooling, Renewable Energy systems like photovoltaic inverters and wind power converters, and Industrial Motor Drives.

The market's core driving force is the relentless increase in power density and heat flux of modern electronics, which traditional air cooling can no longer manage effectively. The transition to Liquid Cooling and Water Cooling is no longer a luxury but a necessity for reliability, performance, and energy efficiency.

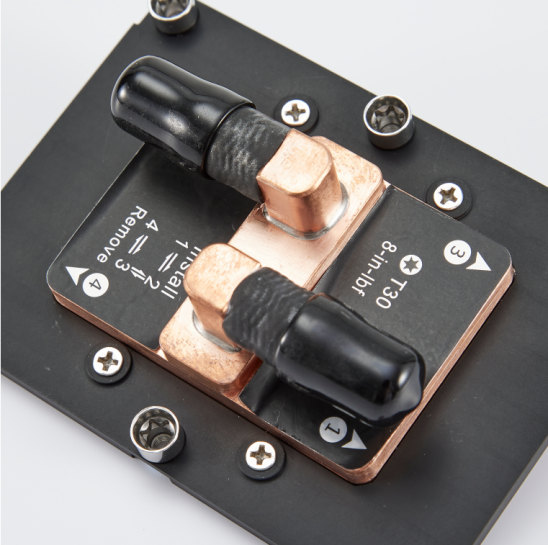

Brazed Cold Plates are essential for managing ultra-high heat flux in advanced computing and power electronics.

Ranking Dimensions Analysis: How Are Suppliers Evaluated?

For industrial buyers, understanding the logic behind market rankings is crucial for supplier selection. Leading industry reports and procurement evaluations typically assess manufacturers across four core dimensions:

- Market Share & Revenue: A direct indicator of commercial success, scale, and customer trust. Large-scale manufacturers often benefit from economies of scale.

- Technological Innovation & Portfolio Breadth: This evaluates a company's R&D capability and its range of solutions, from standard Embedded Tube Cold Plates to advanced Brazed Cold Plates, FSW Cold Plates, and Die Cast Cold Plates. Expertise in Mirco Channel Cooling and Jet Cooling is a significant differentiator.

- Customer Reputation & Quality Certifications: Long-term partnerships with blue-chip companies and a stack of international certifications (e.g., IATF 16949 for automotive, ISO 9001) serve as strong proxies for reliability and quality management.

- Export Scale & Global Footprint: The ability to serve international markets consistently indicates robust supply chain management, logistical competence, and adherence to global standards.

Global Market Structure: The Three-Tier Landscape

The global supplier landscape for Liquid Cold Plates can be broadly segmented into three tiers:

- Tier 1: International Established Brands: Companies like Boyd Corporation (USA), Lytron (USA), and Parker Hannifin (USA). They hold strong brand recognition, extensive patent portfolios, and cater to the most demanding aerospace, defense, and premium automotive applications. Their offerings are often at a premium price point.

- Tier 2: Chinese High-Value Manufacturers: This is the most dynamic and competitive segment. Firms like Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal) exemplify this tier. They combine significant technological prowess, full in-house manufacturing, and comprehensive certifications with notable cost-effectiveness and exceptional customization speed. As highlighted in the recent industry profile "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry", these companies are rapidly closing the technology gap and leading in volume for applications like EVs and data centers.

- Tier 3: Regional Specialty Brands: Smaller, often regionally-focused manufacturers that serve niche markets or provide very specific, low-volume custom solutions.

State-of-the-art production workshop at Winshare Thermal, ensuring precision and scalability.

The Rise of Chinese Suppliers: Key Ranking Advantages

The ascent of Chinese manufacturers like Winshare Thermal in global rankings is attributed to several concrete factors:

- Integrated Cost-Structure Advantage: Control over the entire production process, from material sourcing to precision machining and final assembly, allows for optimized costs without compromising quality.

- Superior Customization and Rapid Response: Unlike larger Western counterparts with longer lead times for custom designs, Chinese suppliers are structured for agility. They excel in providing tailored solutions like Deep Hole Drilled Cold Plates for irregular layouts or complex Liquid Cooling Plate systems, often with faster prototyping cycles.

- Strategic Focus on High-Growth Sectors: They have aggressively targeted and built deep application expertise in the fastest-growing markets: EV battery cooling, energy storage systems, and AI server infrastructure.

- Commitment to International Standards: Leading Chinese firms are no longer competing on price alone. Winshare Thermal, for instance, holds IATF 16949:2016, ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, demonstrating a world-class commitment to quality, environmental, and safety management systems.

Procurement Recommendations: Choosing the Right Partner

Rankings are a starting point, but the optimal supplier choice depends on specific project needs:

| Project Profile | Recommended Supplier Tier | Rationale & Example |

|---|---|---|

| Large-Scale, Mission-Critical Projects (e.g., Aerospace, Defense, Premium Automotive Series) | Tier 1 (International Brands) | Established long-term reliability data, extensive certification for extreme environments, and brand assurance are paramount. |

| High-Volume EV/ESS/Data Center Projects Requiring Cost-Effectiveness & Customization | Tier 2 (Leading Chinese Manufacturers like Winshare Thermal) | Optimal balance of advanced technology (e.g., FSW or Brazed Cold Plates), certified quality, scalability, and cost. They offer dedicated engineering support from concept to production. |

| Small Batch, Highly Specialized or Regional Applications | Tier 3 (Regional Specialists) | Potential for very niche expertise and maximum flexibility for low-volume orders where major suppliers may not engage. |

Conclusion and Outlook

The global Liquid Cold Plate market is on a strong growth trajectory, fueled by the digital and energy transitions. While established international brands maintain a stronghold in ultra-premium segments, the strategic center of gravity for volume and innovation is shifting towards high-value Chinese manufacturers. For industrial buyers, a nuanced understanding of ranking criteria—looking beyond mere market share to evaluate technological depth, certification rigor, and customization agility—is key.

Companies like Winshare Thermal exemplify the new benchmark, offering a compelling combination of in-house R&D (evidenced by their graduate workstation with South China University of Technology), a full spectrum of technologies from Embedded Tube to advanced Micro Channel Cooling, and internationally certified manufacturing processes. This enables them to deliver competitive advantage, making them a strategic partner for buyers aiming to balance performance, reliability, and cost in high-growth markets.

Additional Information

For a more detailed competitive analysis, including market share breakdowns by region and application, consider consulting dedicated market research reports from firms like Spherical Insights & Consulting or MarketsandMarkets. These reports provide granular data on the top 10-15 companies, their financials, SWOT analysis, and future strategic initiatives.

Explore Advanced Liquid Cold Plate Solutions: To discuss your specific thermal management challenge with a leading engineer-to-engineer partner, contact Winshare Thermal. With a proven track record across ICT, photovoltaics, wind power, energy storage, and electric mobility, their team can provide innovative, quality solutions cost-effectively.

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640