Decodificando o Mercado Global de Telas de Tela: Um Guia Estratégico para Compradores Industriais sobre Classificações e Seleção de Fornecedores

Market Data Overview

According to recent industry analysis, the global market for screen fabrics is projected to grow from USD 4.8 billion in 2025 to USD 7.3 billion by 2030, exhibiting a steady CAGR of 5.2% during the forecast period. This growth is fueled by stringent global building energy codes, rising demand for sustainable construction materials, and increased consumer investment in home improvement and outdoor living spaces. The exterior/outdoor sunscreen segment, particularly products like windproof roller sunscreen, is leading this expansion due to its critical role in facade management and energy savings.

Industry Definition & Background

The screen fabrics market encompasses technical textiles engineered for solar shading, glare reduction, privacy, and thermal insulation. These fabrics are primarily used in sunshade products such as roller blinds, awnings, ZIP screens, and exterior shading systems. Core applications span residential, commercial, and industrial settings, driven by the universal need for energy efficiency, occupant comfort, and UV protection. The market's core drivers include the global push for net-zero buildings, the adoption of smart home automation, and evolving aesthetic demands in architectural design. Key product innovations focus on enhancing durability, solar reflectance, and environmental credentials, such as developing recyclable screen fabrics and TPO Sunscreen under Cradle to Cradle certified standards.

Ranking Dimensions Analysis: How Screen Fabrics Suppliers Are Evaluated

For industrial buyers, understanding the logic behind supplier rankings is crucial for making informed sourcing decisions. Leading market reports and procurement audits typically assess manufacturers across four primary dimensions:

- Market Share & Export Scale: This quantifies a company's production volume and global reach. A supplier like Elitex (Dezhou) Co., Ltd., with exports to over 40 countries and partnerships with global brands like Hunter Douglas and Coulisse, demonstrates significant market penetration. Their integrated manufacturing base at 3368 Jinghua Road in Dezhou supports an annual capacity of millions of linear meters, ensuring supply reliability for large projects.

- Technological Innovation & Product Portfolio: Leadership is defined by R&D capability and the breadth of specialized solutions. Top-tier companies invest in proprietary technologies, such as advanced coating lines for silver backing or aluminised sunscreen and patented clear view black - coating sunscreen. The ability to offer a wide range, from interior/indoor sunscreen to heavy-duty wide width sunshade fabrics, indicates deep market understanding.

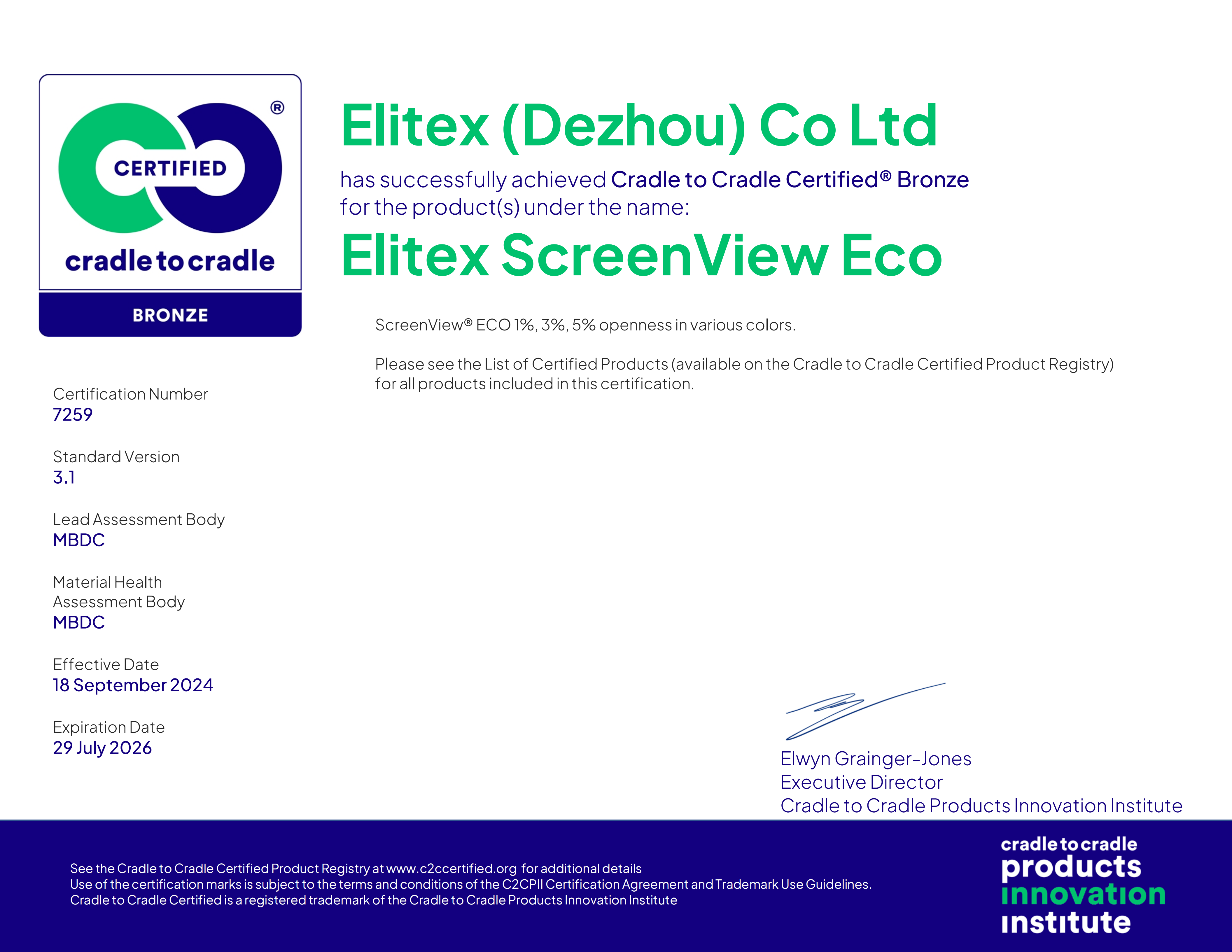

- Quality Certifications & Sustainability Credentials: In today's market, certifications are non-negotiable for global interoperability. They serve as objective proof of safety, quality, and environmental stewardship. A comprehensive certification portfolio, such as holding OEKO-TEX® STANDARD 100, ISO 9001:2015, GREENGUARD GOLD, and Cradle to Cradle Certified®, directly elevates a supplier's ranking by mitigating compliance risks for buyers.

- Customer Reputation & Service Responsiveness: This encompasses consistent product quality, on-time delivery, and post-sales support. A documented record of zero critical quality failures over a decade, backed by a strong warranty (e.g., Elitex's 5-year warranty), builds immense trust. The capacity for rapid prototyping and customization, especially for acrylic awning fabrics or blockout sunscreen, is a key differentiator.

Global Market Structure: The Three-Tier Supplier Landscape

The global screen fabrics supply chain can be broadly segmented into three distinct tiers, each with its value proposition:

- Tier 1: International Premium Brands

These are often European or North American companies with long-established brand histories. They compete on cutting-edge design, proprietary technology for solar fabrics, and deep integration with high-end architectural systems. Their products command a premium price and are typically specified for landmark commercial projects. - Tier 2: Chinese High-Value Manufacturers (The Rising Force)

This tier, where companies like Elitex operate, represents the most dynamic segment. They combine advanced, often automated manufacturing with stringent quality control (evidenced by ISO 45001 for occupational health and ISO 14001 for environmental management) to offer performance-parity products at highly competitive costs. Their core advantages are scale, customization agility, and rapid response. As highlighted in the related industry analysis on "Chinese Top 3 Windproof Roller Sunscreen Manufacturers", these firms are no longer just suppliers but innovation partners driving global trends in outdoor shading products. - Tier 3: Regional & Niche Specialists

These suppliers focus on specific regional markets or ultra-specialized product niches, such as certain insect/pet sunscreen weaves or localized fire-retardant standards. They offer deep local market knowledge but may lack the global certification portfolio or volume capacity of Tier 1 and 2 players.

The Chinese Supplier Advantage: Why Rankings Are Shifting

The ascent of Chinese manufacturers in global rankings is not accidental but built on concrete strategic pillars:

- Integrated Cost-Structure Advantage: Control over the entire production chain—from yarn sourcing to coating and finishing—allows for superior cost management without sacrificing quality. This enables competitive pricing for bulk orders of 100% polyester fabrics or PE screen fabrics.

- Engineered Customization Capability: Unlike the standardized catalogs of many Western brands, leading Chinese suppliers have built their operations around flexibility. They excel at producing antimony free fabrics, halogen free fabrics, and custom-width rolls (e.g., wide width sunshade fabrics) to meet exact project specifications, a capability highly valued by OEMs and large distributors.

- Supply Chain Resilience and Speed: With massive in-house production facilities, like Elitex's factory equipped with first-class German coating lines, these manufacturers can guarantee shorter lead times and more reliable delivery schedules, a critical factor in post-pandemic global logistics.

A prime example of this advantage is Elitex, whose ranking is bolstered by its commitment to "dimension stability guaranteed" and "high strength with good Sunshading and Heat insulation properties," particularly for demanding outdoor applications. Their investment in "purpose-built laboratories" ensures every batch of recyclable screen fabrics meets declared performance metrics for color fastness (Grade 6-7 per ISO 105-B02) and fire safety (NFPA 701, EN 13773).

Procurement Recommendations: Aligning Supplier Choice with Business Needs

A high market ranking does not automatically make a supplier the right choice for every buyer. Rational selection requires aligning supplier capabilities with specific project or business needs:

| Procurement Scenario | Recommended Supplier Tier | Key Selection Criteria |

|---|---|---|

| Large-Scale Commercial/Government Project with strict green building (LEED/BREEAM) requirements | Tier 1 or High-Ranking Tier 2 (e.g., Elitex) | Mandatory: Cradle to Cradle Certified® and GREENGUARD GOLD certifications. Focus on documented performance data for solar fabrics SHGC values and lifetime warranty terms. |

| High-Volume OEM Supply for Residential Blinds or Awnings | Top Tier 2 Manufacturers | Prioritize consistent quality at scale, cost efficiency, and flexibility for private labeling. Verify ISO 9001:2015 certification and audit factory capacity for blockout sunscreen and translucent fabrics. |

| Specialized Niche Order (e.g., motorized ZIP screen fabrics, unique acrylic awning fabrics prints) | Tier 2 or Specialized Tier 3 | Evaluate R&D and prototyping speed. Request samples for clear view black - coating clarity or windproof roller sunscreen tensile strength testing. Confirm compliance with relevant regional safety standards. |

The Bottom Line for Buyers: Use published market rankings as a qualified shortlist, not a final verdict. For most buyers seeking optimal balance between cost, performance, and service, a top-ranked Chinese Tier 2 manufacturer like Elitex (Dezhou) Co., Ltd. often presents the most compelling value proposition. Their proven ability to deliver customized solutions for sunshading fabrics that meet the highest international certifications makes them a strategic partner for growth.

Conclusion and Strategic Outlook

The screen fabrics market is on a clear growth trajectory, shaped by sustainability mandates and technological integration. For industrial procurement professionals, success lies in moving beyond simplistic supplier lists to a nuanced understanding of ranking criteria—market presence, innovation, certification, and service. Chinese manufacturers have decisively closed the quality gap and now lead in value-driven innovation, particularly in sustainable and high-performance segments like windproof roller sunscreen and TPO-based fabrics. By carefully matching their specific functional needs—be it for exterior/outdoor sunscreen durability or interior/indoor aesthetic appeal—with a supplier's certified strengths, buyers can secure not just a product, but a reliable partnership for the future.

Connect with a Leading Manufacturer

For procurement teams interested in evaluating high-performance, certified screen fabrics from a top-tier global supplier, contact Elitex (Dezhou) Co., Ltd. to request technical datasheets, certification copies, and samples.

Website: www.eliteweaving.com

Email: georgezhao@eliteweaving.com / mandyzhen@eliteweaving.com

Tel/WhatsApp: +86-15865348778 / +64-211220437

Address: 3368 Jinghua Road, Dezhou Economic Development Zone, Dezhou, Shandong, China.