Como escolher o gerador diesel certo para o seu data center: um guia abrangente do comprador

How to Choose the Right Diesel Generator for Your Data Center: A Comprehensive Buyer's Guide

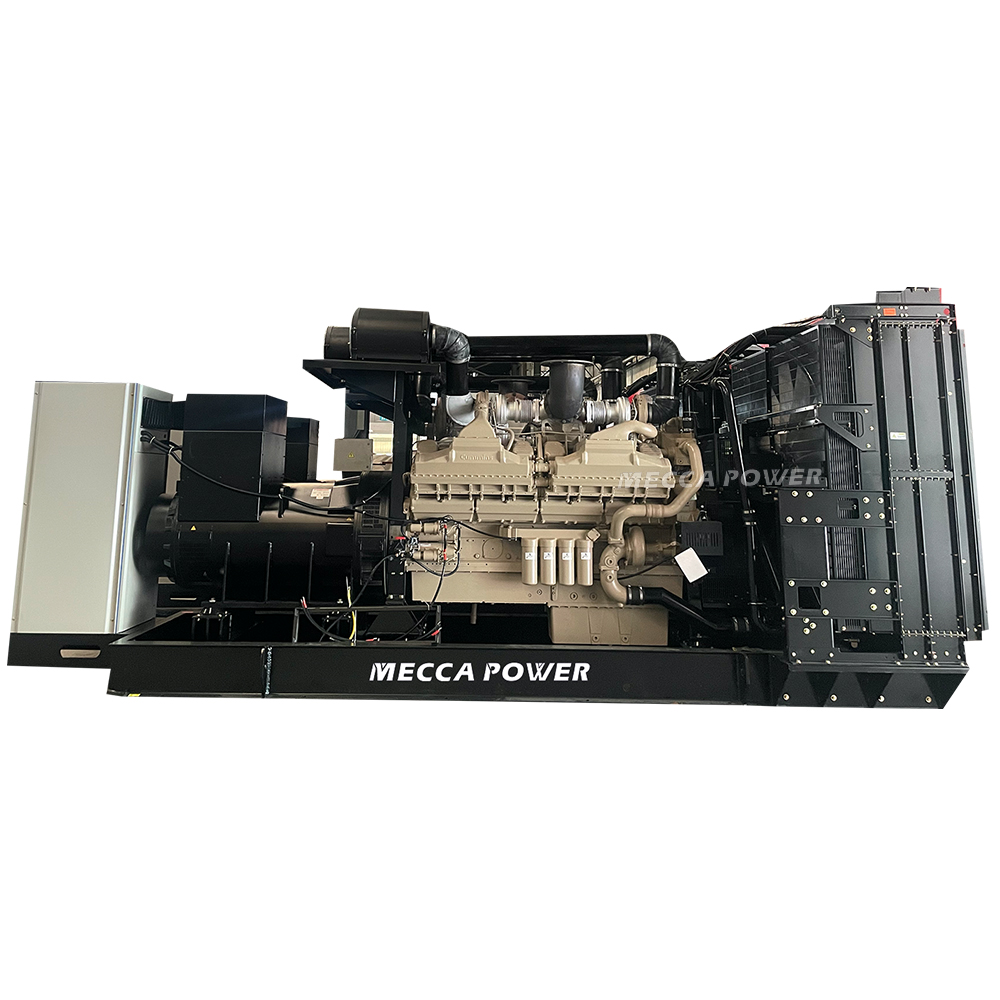

In an era where data is the new currency, ensuring uninterrupted power for data centers is non-negotiable. A reliable diesel generator is the backbone of any robust data center power solution. However, selecting the right unit involves more than just picking the highest kW rating. This guide will walk you through the critical factors, from power sizing and fuel efficiency to testing protocols and supplier selection, helping you make an informed decision for your mission-critical infrastructure.

Why This Guide Matters

With the global surge in cloud computing, AI, and IoT, data center power demands are skyrocketing. A poorly selected generator can lead to catastrophic downtime, equipment damage, and financial loss. This guide leverages industry expertise to help you navigate the complex landscape of diesel generator for data center applications.

Step 1: Accurately Determine Your Power Requirements

The first and most crucial step is sizing. An undersized generator will fail under load, while an oversized one operates inefficiently, leading to higher fuel costs and maintenance issues ("wet stacking").

- Calculate Total Load: Sum the power consumption (in kW or kVA) of all IT equipment, cooling systems (CRAC/CRAH units), lighting, and security systems. Always include future expansion plans.

- Consider Starting Currents: Motors in HVAC systems can have starting currents 3-6 times their running current. Your diesel generator must handle these surges.

- Common Data Center Sizes: Popular models include the 1800KW diesel generator for data center, 2MW diesel generator, and 2500KVA diesel generator for data center. For massive hyperscale facilities, modular solutions or 10MW power plant diesel generator setups are considered.

Pro Tip: Consult with a professional data center power solution supplier like MECCA POWER for a detailed load audit. They can simulate your power profile to recommend the perfect size.

Step 2: Evaluate Key Generator Features & Specifications

Not all generators are created equal. Here are the specifications that matter most for a 24/7 data center environment:

| Feature | Why It's Important for Data Centers | What to Look For |

|---|---|---|

| Engine Brand & Tier | Determines reliability, fuel efficiency, and emissions compliance. | Top-tier partners like Cummins, MTU, Perkins, Volvo. Reputable Diesel Generator manufacturer like MECCA POWER uses these engines, ensuring quality and global service support. |

| Alternator (Generator End) | Produces clean, stable power essential for sensitive servers. | Brands like Stamford, Leroy Somer, Mecc Alte. Low harmonic distortion (THD <5%). |

| Control System | Enables monitoring, automatic transfer, and remote management. | Digital controllers from DeepSea or ComAp with cloud connectivity for remote diagnostics. |

| Fuel System & Runtime | Ensures extended operation during prolonged outages. | Large base fuel tank or connection to bulk storage. Options for containerized generator for data center with integrated fuel systems. |

| Emissions & Sound Level | Compliance with local regulations and community standards. | EPA Tier 4 Final or equivalent. Canopied or containerized generator designs for significant noise attenuation. |

Step 3: Understand the Critical Role of Load Bank Testing

One of the most overlooked aspects of data center power reliability is regular generator testing under real load conditions. This is where a load bank is indispensable.

- What is a Load Bank Test? It's a test that applies an artificial electrical load to the generator to validate its performance at its rated capacity.

- Why It's Mandatory for Data Centers: Prevents "wet stacking" (unburned fuel accumulation in diesel engines running lightly loaded), verifies cooling system performance, and ensures the generator will perform when called upon in a real outage. A dedicated load bank for generator test is a critical asset.

- Choosing a Load Bank: Work with a reputable load bank manufacturer. The load bank must match the generator's voltage, phase, and power rating (e.g., a 2MW diesel generator requires a compatible 2MW load bank).

MECCA POWER, as both a premier Diesel Generator manufacturer and a load bank manufacturer, provides integrated load bank for data center solutions, ensuring your backup power system is always mission-ready.

Step 4: Assess the Manufacturer's Capabilities & Credentials

The supplier's expertise is as important as the product's specs. For a Large power project supplier, you need proven capability.

- Manufacturing Scale & Quality Control: Does the company have its own factory? MECCA POWER operates self-owned factories in Fujian and Jiangxi provinces, with a specialized high-power production line in Nanchang capable of monthly outputs exceeding 200 units, including simultaneous testing of three 2000KW+ units. Their production leverages APS+MES systems for digital, traceable quality control.

- Technical Expertise & EPC Experience: Can they handle complex projects? MECCA POWER has extensive experience in domestic and international power plant EPC projects, providing end-to-end technical support from design to commissioning.

- Certifications & Partnerships: Look for international quality (ISO 9001) and safety certifications. MECCA POWER holds CE Certificate and is an authorized OEM for world-leading engine brands like Cummins, Perkins, MTU, Volvo, and alternator brands like Stamford and Leroy Somer. This ensures genuine parts and global service alignment.

- After-Sales & Global Support: Ensure they offer comprehensive warranty, remote monitoring, and readily available spare parts. A true partner provides lifecycle support.

Step 5: Consider Total Cost of Ownership (TCO), Not Just Price

The initial purchase price is just one component. A cheaper, low-quality unit can cost exponentially more over 10-15 years.

- Fuel Efficiency: A more efficient engine (g/kWh) saves thousands in fuel costs over its life.

- Maintenance Costs: Units with standard, globally available engine parts (like those from MECCA's partner brands) have lower and more predictable maintenance costs.

- Reliability & Downtime Cost: The cost of a single data center outage can dwarf the generator's price. Investing in a reliable system from a proven Diesel Generator manufacturer is insurance.

- Solution vs. Product: Does the supplier offer a complete data center power solution, including switchgear, paralleling systems, and sound-attenuated enclosures? An integrated solution from a single responsible supplier like MECCA POWER reduces interface risks and simplifies project management.

Making the Final Decision: Why MECCA POWER Stands Out

Choosing a diesel generator for data center is a strategic decision. MECCA POWER distinguishes itself as a Large power project supplier by offering:

- Vertical Integration: From self-owned R&D and manufacturing to testing with their own load banks, they control quality at every step.

- Power Range & Flexibility: Products from 10kVA to 4000kVA, including critical models like the 1800KW, 2MW, and 2500KVA diesel generator, in open or containerized designs.

- Proven Track Record: Successful deployments in Telecom, Data Centers, Mining, and power plant projects globally.

- One-Stop Support: As a professional data center power solution supplier, they provide design, production, application support, and after-sales maintenance.

Ready to secure your data center's power future? Contact the experts at MECCA POWER for a customized solution.

Website: www.meccapower.com.cn

Email: mecca@meccagen.com

Phone/WhatsApp: +86 15659994455

Address: Room 11, 10th Floor, Building A1#, Cangshan Wanda Plaza, Fuzhou, Fujian Province, China.