Como escolher o gerador diesel certo para o seu projeto de energia em grande escala: um guia abrangente do comprador pela MECCA POWER

The Ultimate Guide to Selecting a Diesel Generator for Large Power Projects

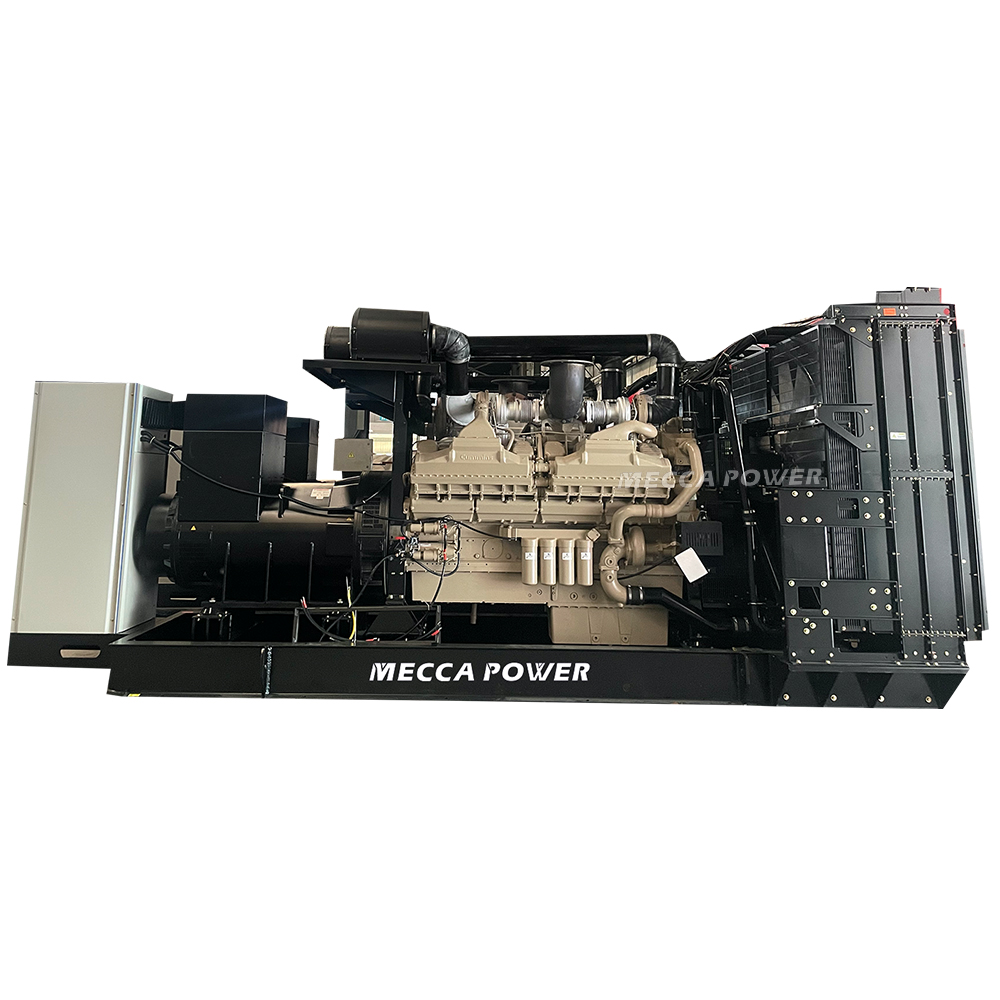

In an era defined by rapid infrastructure development and the critical need for uninterrupted power, selecting the right diesel generator is not merely a procurement decision—it's a strategic investment in operational continuity and project success. Whether you're powering a remote mining operation, a hyperscale data center, a sprawling construction site, or a dedicated power plant, the stakes are incredibly high. This comprehensive buyer's guide, crafted by MECCA POWER, a leading Diesel Generator manufacturer and Large power project supplier, will walk you through the critical steps to ensure you choose a generator that delivers reliability, efficiency, and value for your specific large-scale application.

Why This Guide Matters

With over two decades of experience in designing and manufacturing diesel generators from 10kVA to 4000kVA, and executing complex power plant EPC projects globally, MECCA POWER understands the nuanced demands of critical sectors like Oil & Gas, Telecom, and Power Plants. Our guide leverages this deep industry knowledge to help you navigate the complexities of generator selection.

Step 1: Pre-Selection Analysis – Defining Your Power Needs

Before evaluating any Diesel Generator, a thorough analysis of your project's requirements is essential.

- Application & Load Profile: Is this for prime power, continuous operation, or standby/backup? A diesel generator for data center requires different specifications than a diesel generator for mining used for prime power. Understand your base load, peak load, and the nature of the loads (motor starting, sensitive electronics).

- Power Capacity (kVA/kW): Accurately calculate your total connected load and required running capacity. For large projects, consider modular or parallel systems. MECCA POWER specializes in high-capacity units like the 1800KW diesel generator for data center, 2MW diesel generator for data center/construction/Mining, and even massive 10MW and 50MW power plant diesel generator systems.

- Site Conditions & Environment: Consider altitude, ambient temperature, humidity, and exposure to corrosive elements (common in oil gas and mining). This dictates the need for derating and specific engine features.

- Fuel Availability and Regulations: Assess local fuel quality and emissions regulations, which may influence the choice of engine technology and after-treatment systems.

A containerized generator for data center by MECCA POWER, offering integrated protection and ease of deployment for large-scale projects.

Step 2: Core Component Evaluation – The Heart of Reliability

The quality of core components directly determines the generator's lifespan and performance.

| Component | Key Considerations | MECCA POWER's Assurance |

|---|---|---|

| Engine | Brand reputation, fuel efficiency, emissions compliance, service network, power density. | As a prestigious OEM, we partner with world-leading brands like Cummins, Perkins, MTU, Mitsubishi, VOLVO, Baudouin, and reputable Chinese engine brands, offering optimal choices for every budget and performance need. |

| Alternator | Electrical performance, voltage regulation, ability to handle non-linear loads, insulation class. | We use premium alternators from Stamford, Leroy Somer, Mecc Alte, and Kwise, ensuring clean, stable power output critical for sensitive data center power solutions. |

| Control System | Automation level, remote monitoring (SCADA/Genset Link), paralleling capability, user interface. | We integrate intelligent controllers from DeepSea and ComAp, enabling advanced features for monitoring and control, a hallmark of our professional solution. |

Step 3: Configuration & Customization – Tailoring the Solution

Off-the-shelf units rarely suffice for large projects. Look for a manufacturer with strong engineering and customization capabilities.

- Enclosure Type: Open skid, canopy (silent type), or containerized generator? Containerized solutions offer superior protection, sound attenuation, and integrated systems, ideal for harsh environments or data center applications.

- Fuel System: Base tank size, day tank requirements, and fuel polishing systems. For remote Telecom sites, a Telecom Diesel Generator with Big Fuel Tank is crucial for extended runtime.

- Cooling & Exhaust: Radiator size, ambient capability, and critical silencer specifications for noise compliance.

- Parallel Operation: For projects requiring 2500KVA or 10MW+, ensure the manufacturer has proven experience in designing and synchronizing multiple generator sets.

Step 4: Manufacturing & Quality Assurance – The Foundation of Trust

A generator is only as good as the factory that builds it. Investigate the manufacturer's production capabilities and quality control.

MECCA POWER operates state-of-the-art factories in Fujian and Jiangxi provinces. Our Nanchang factory, specializing in units of 1000kW and above, features:

- Three specialized production lines (container, open-type, mixed-assembly).

- Six advanced testing stations with digital tightening and cloud-based data management.

- A 45-ton lifting capacity, enabling simultaneous testing of three units over 2000KW.

- Implementation of APS+MES systems for efficient production control.

This robust infrastructure, backed by our self-owned factory assets and independent R&D team, ensures every Diesel Generator is built to the highest standards.

Step 5: The Non-Negotiable: Commissioning & Load Bank Testing

This is the most critical yet often overlooked step. Never accept a generator without proper factory acceptance testing (FAT) using a load bank.

Why Load Bank Testing is Essential:

- Validates Performance: Confirms the generator can deliver rated power (e.g., 1800KW, 2MW) at specified voltage and frequency under full load.

- Burns off Glaze: Prevents "wet stacking" in diesel engines, a common issue in standby units that rarely run under load.

- Tests Control Logic: Verifies automatic transfer switches, load sharing, and protection systems function correctly.

- Critical for Data Centers: A load bank for data center commissioning is mandatory to simulate IT load and ensure the entire backup system is mission-ready.

As both a premier Diesel Generator manufacturer and a Load bank manufacturer, MECCA POWER provides integrated load bank for generator test solutions. We rigorously test every unit before shipment, ensuring it arrives on site ready for reliable operation in your power grid or facility.

Step 6: Certifications, Support, and Total Cost of Ownership (TCO)

Finally, evaluate the supplier's credentials and long-term value proposition.

- Certifications: Demand proof of international certifications. MECCA POWER holds the CE Certificate and is an authorized OEM for major engine brands (as evidenced by our PERKINS OEM, MTU, Deutz OEM, Leroy Somer certificates), guaranteeing genuine parts and manufacturer-backed quality.

- After-Sales & Technical Support: A global supplier must offer comprehensive support. MECCA POWER provides lifelong technical support and after-sales maintenance, drawing from our vast power plant EPC experience.

- Calculate TCO: Look beyond the initial price. Factor in fuel consumption, maintenance costs, expected lifespan, and the cost of downtime. A reliable, efficient generator from a trusted Large power project supplier like MECCA POWER minimizes TCO over its lifecycle.

Ready to Power Your Project with Confidence?

Choosing the right diesel generator is a complex but vital process. By following this guide and partnering with an experienced, vertically-integrated manufacturer like MECCA POWER, you secure more than just equipment—you gain a reliable partner for your critical power needs.

Contact MECCA POWER today for a customized professional solution tailored to your diesel generator for data center, mining, construction, or power plant project.

Website: www.meccapower.com.cn

Phone/WhatsApp: +86 15659994455

Email: mecca@meccagen.com