Como escolher a máquina de desenho multifio certa: um guia abrangente do comprador para fabricantes de fios e cabos

How to Choose the Right Multiwire Drawing Machine: A Comprehensive Buyer's Guide

Selecting the optimal multiwire drawing machine is a critical capital investment decision for any wire and cable machine manufacturers or production facility. The right equipment directly impacts productivity, product quality, operational costs, and long-term competitiveness. This guide, informed by the expertise of industry leader HONTA, will walk you through the key considerations, technical specifications, and strategic factors to ensure you make an informed purchase that aligns with your production goals.

Understanding Your Core Requirements

Before evaluating specific HONTA wire drawing machine models or other brands, clearly define your production needs:

- Material Type: Are you processing copper, aluminum, or both? This determines whether you need a dedicated copper rod breakdown machine, an aluminium rod breakdown machine, or a versatile rod breakdown machine for copper and aluminium.

- Final Wire Gauge & Output: Define your target diameter range (e.g., 0.10mm to 1.37mm) and required production speed. This will guide you toward an 8 wires multiwire drawing machine, 16 wires, 24 wires, or even a high-capacity 32 wires multiwire drawing machine.

- Annealing Requirement: Do you need in-line softening? If yes, a rod breakdown with annealer machine or a system with an inline annealer machine is essential for producing soft or annealed wire in a single pass.

- Take-up System: Consider your spooling needs. Options include a single spooler, double spooler, or a basket coiler for larger, non-spooled coils.

Key Technical Features to Evaluate

Once requirements are set, dive into the machine's technical architecture. Leading manufacturers like HONTA offer advanced configurations.

1. Drive System: Individual Motors vs. Traditional Drives

The drive system is the heart of a multiwire drawing machine. A rod breakdown machine with individual motors or an individual motors multiwire drawing machine represents the pinnacle of modern design. Each drawing capstan has its own servo motor, allowing for:

- Precise Speed & Tension Control: Independent control eliminates cumulative speed errors, ensuring consistent wire quality across all wires.

- Enhanced Flexibility: Easy setup for different wire sizes and materials without changing mechanical gearboxes.

- Reduced Maintenance: No complex gear train means fewer wear parts and lower long-term costs.

Compared to traditional single-motor drives with gearboxes, the individual motors system, as perfected in HONTA machine designs, offers superior performance for demanding applications.

HONTA's advanced Multi-Motor Rod Breakdown lines exemplify the precision and flexibility of individual motor drive technology.

2. Integration of Annealing and Take-Up

For efficiency, consider integrated lines. A complete wire and cable equipment line from a single supplier like HONTA ensures compatibility. Look for:

- Inline Annealer Machine: Integrated directly after the final drawing die. A rod breakdown with annealer machine streamlines production of soft copper or aluminum wire, saving space and energy compared to a separate batch process.

- Wire Take Up Machine: The final stage must be reliable and high-speed. Options like a double spooler allow for continuous operation—one spool fills while the other is doffed. For larger volumes, a robust basket coiler is ideal.

HONTA's On-line Annealer provides seamless in-line softening, a key feature in modern wire drawing lines.

The Manufacturer Selection: Beyond the Machine Specs

Your choice of wire and cable machinery supplier is as important as the machine itself. Evaluate potential partners on these criteria:

Company Credentials and Global Support

Established in 2006, HONTA has grown into a large cable machine system service provider. Key indicators of a reliable partner include:

- Global Presence: With its second production base, HONTA INC., established in the USA in 2017, the company demonstrates commitment to international support and understanding of global markets.

- Industry Recognition: Long-term cooperation with well-known cable companies worldwide is a strong testament to product reliability and performance.

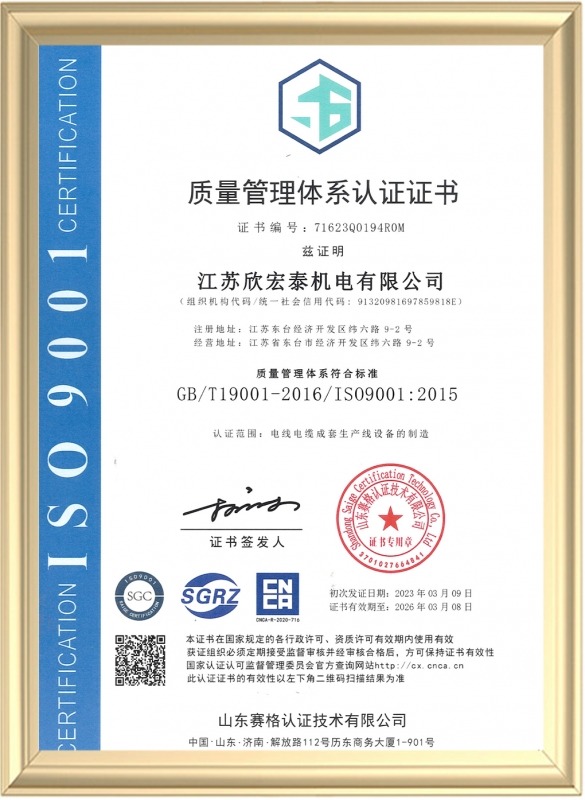

- Certifications: Always verify international quality and environmental standards. HONTA holds ISO 9001 Certification for quality management and ISO 14001 Certification for environmental management, alongside UDEM International Certification, assuring adherence to rigorous manufacturing protocols.

Production Capability and R&D Focus

Visit the factory or review production evidence. HONTA's main products, including the multiwire drawing line and high-speed stranding equipment, are renowned for high speed, efficiency, automation, and humanization. A strong R&D department focused on cable conductor drawing and stranding technology is crucial for future-proofing your investment.

HONTA's modern production facility, a base for innovation in wire and cable equipment.

Making the Final Decision: Total Cost of Ownership (TCO)

Look beyond the initial purchase price. Calculate the Total Cost of Ownership, which includes:

- Energy Consumption: Modern individual motors multiwire drawing machine designs are often more energy-efficient.

- Maintenance & Spare Parts: Assess the availability and cost of spare parts. A supplier with a global footprint like HONTA offers better support.

- Downtime: High-reliability machines and responsive after-sales service minimize costly production stoppages.

- Output Quality & Yield: A machine that produces consistent, high-quality wire with minimal breakage reduces material waste and increases profitability.

Your Next Step with HONTA

Choosing the right multiwire drawing machine is a strategic decision. As a leading wire and cable equipment manufacturer, HONTA provides not just machines, but comprehensive solutions—from the copper rod breakdown machine to the final wire take up machine.

We encourage you to engage with their technical team to discuss your specific needs for an 8, 16, 24, or 32 wires multiwire drawing machine, rod breakdown with annealer machine, or customized wire & cable machinery solutions.

Contact HONTA Today for a Detailed Consultation:

Phone: +86 182 6287 9467

WhatsApp: +86 187 5292 2675

WeChat: wtammy0631

Email: tammy@jshonta.com

Website: www.jshonta.com / www.kshonta.com

Address: Room 1219, Building 3, Dongchuang Technology Center, Qianjin East Road, Kunshan City, Jiangsu Province, China. Zip:215300

By meticulously following this guide and partnering with an established, innovative, and certified manufacturer like HONTA, you can confidently select a multiwire drawing machine that will drive efficiency, quality, and growth for your wire and cable manufacturing operations for years to come.