Como escolher a máquina de saco de papel certa para o seu negócio: um guia abrangente do comprador

How to Choose the Right Paper Bag Machine for Your Business: A Comprehensive Buyer's Guide

The global shift towards sustainable packaging has created a booming demand for paper bags. Whether you're a startup, a growing packaging converter, or an established manufacturer looking to expand, investing in the right paper bag machine is a critical decision. With various types like flat bottom paper bag machines and square bottom paper bag machines available, selecting the ideal equipment can be daunting. This comprehensive buyer's guide will walk you through the key factors, technical considerations, and strategic questions to ask, helping you make an informed investment that boosts your productivity and profitability.

Why Your Choice of Paper Bag Machine Matters

Choosing the correct paper packet making machine is not just about the initial automatic paper bag machine price. It's about total cost of ownership, production efficiency, bag quality, and your ability to meet diverse market demands. The right machine from a reputable manufacturer like Ruizhi Machinery can be a game-changer, enabling you to produce high-quality, eco-friendly bags for retail, food service, gifts, and more, while ensuring a strong return on investment.

Step 1: Define Your Production Needs and Goals

Before comparing models or prices, clearly outline your business requirements:

- Bag Type & Design: What kind of bags do you need? Common types include:

- Square Bottom Paper Bags: Also known as block bottom or flat bottom bags, these are sturdy and ideal for retail shopping, clothing, and gifts. Machines like the RZFD-190 Square Bottom Paper Bag Machine are designed for this.

- Flat Bottom Paper Bags: Similar to square bottom but may refer to specific construction. Ruizhi Machinery specializes in both.

- Pouches: For lighter items. A versatile paper pouch packing machine might be needed.

- Do you need handles (flat rope, round rope), windows, or printing capabilities?

- Production Volume & Speed: Estimate your daily/weekly output needs. Automatic machines offer higher speeds. For instance, the RZFD-330T Fully Automatic Square Bottom Paper Bag Machine with auto-stacking is built for high-volume production.

- Raw Material: Determine the paper grammage (GSM), roll width, and type (kraft, recycled, coated) you plan to use. Ensure the machine is compatible.

- Future Expansion: Consider if you might need to add features later, like an integrated printer. Models like the RZFD-190 with Integrated 2-Color Printing Unit offer this flexibility.

Ruizhi Machinery's RZFD-190 Square Bottom Paper Bag Machine - A versatile solution for producing high-quality retail bags.

Step 2: Understand the Different Types of Machines

Knowing the machine categories will narrow your search:

| Machine Type | Best For | Key Features |

|---|---|---|

| Semi-Automatic | Startups, low-volume, custom orders | Lower automatic paper bag machine price, more manual intervention, flexible for short runs. |

| Fully Automatic | Medium to high-volume production | High speed, minimal labor, often include auto-feeding, gluing, punching, and stacking. Example: RZFD-330IF Flat Rope Inside Folding model. |

| Integrated Printing Lines | Brands needing custom printed bags | Combines bag making and flexographic printing in one line, like the RZJD-G350J with 4-Color Printing. |

Step 3: Evaluate Technical Specifications & Manufacturer Credibility

This is where partnering with an established manufacturer like Wenzhou Ruizhi Packing Machinery Co., Ltd. becomes crucial. Don't just look at specs on paper; assess the builder's reputation.

A. Key Technical Points to Scrutinize:

- Speed (Bags/Minute): Match it to your volume needs.

- Automation Level: Look for features like automatic tension control, fault detection (as in the RZFD-330T), and stack counting.

- Flexibility: Can the machine handle different paper weights and bag sizes with quick changeovers?

- Construction & Components: Inquire about the quality of PLC systems, servos, guides, and glue systems. Robust construction ensures longevity.

B. Assessing the Manufacturer: Why Ruizhi Machinery Stands Out

When evaluating a supplier for your paper bag machine, consider these pillars of credibility that Ruizhi embodies:

- Experience & Scale: Established in 2003, Ruizhi has over two decades of focused R&D in environmentally friendly paper bag making machines. They have a technical team with more than 20 years of experience.

- Innovation & R&D: With dozens of senior R&D engineers, Ruizhi continuously innovates. Their product range, from the RZFD-190W Square Bottom Windowed Paper Bag Machine to advanced automatic models, showcases their technical prowess.

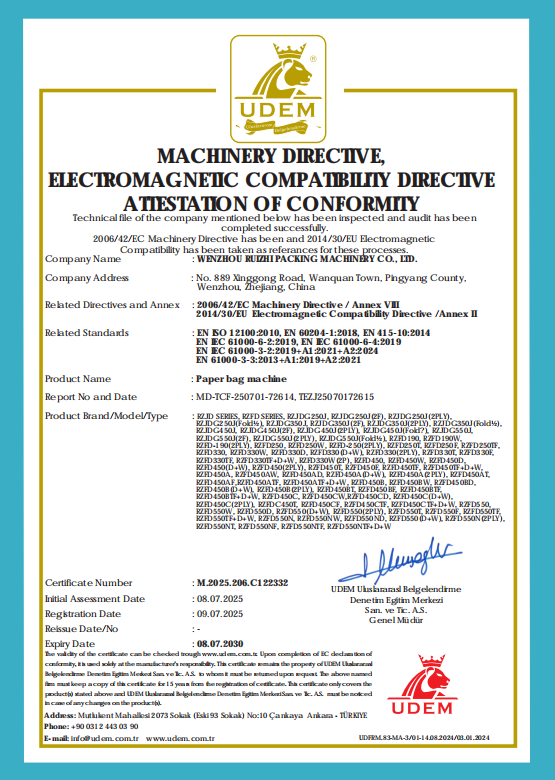

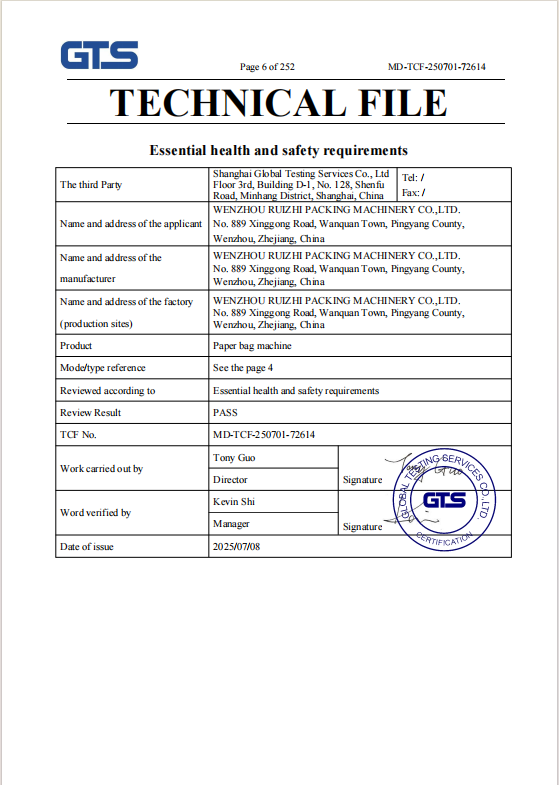

- Quality Certifications: This is non-negotiable. Ruizhi's machines strictly implement ISO9001 quality system standards and carry CE safety certification. They also provide essential documentation like the EMC Technical File and UDEM Certificate, ensuring compliance for export to markets like Europe and Turkey.

- Global Reach & Service: Their equipment is exported to over 60 countries, including Spain, the Middle East, and Africa. A global footprint indicates reliable performance. They offer comprehensive services: technical consultation, installation, training, and after-sales support.

UDEM Certificate

CE Certification

Step 4: Analyze Costs Beyond the Purchase Price

The automatic paper bag machine price is just the beginning. Consider Total Cost of Ownership (TCO):

- Initial Investment: Machine price, shipping, and installation.

- Operational Costs: Energy consumption, labor (lower for automatics), glue/ink consumption, and maintenance parts.

- Efficiency Gains: A faster, more reliable machine from Ruizhi reduces waste and increases output, paying for itself over time.

- After-Sales Value: Free technical support, availability of spare parts, and training provided by the manufacturer. Ruizhi's commitment to "complete after-sales service as the guarantee" directly lowers your long-term TCO.

Step 5: Request Demos and Check References

Always ask for a live or recorded video demonstration of the specific machine model (e.g., RZJD-G350 Dual Unwinding Paper Bag Machine) producing bags similar to your target. Request contact information for existing clients in your region or a similar industry. A confident manufacturer like Ruizhi will be transparent.

Making the Final Decision: Partner with Ruizhi Machinery

Choosing a paper bag machine is choosing a long-term partner for your business growth. Wenzhou Ruizhi Packing Machinery Co., Ltd. presents a compelling proposition:

- Product Range: From standard square bottom paper bag machines to complex automated lines with printing, they have a solution.

- Proven Quality & Safety: Backed by ISO9001 and CE, ensuring durable and safe operation.

- Global Support: Their experience in exporting to over 60 countries means they understand international client needs.

- Innovation-Driven: Continuously developing new equipment like the RZFD-330W Windowed Paper Bag Machine to meet market trends.

By following this guide, you move from asking "what is the price?" to understanding "what is the best value for my specific needs?" The goal is not just to buy a machine, but to invest in a productivity system that will deliver returns for years to come.

Ready to take the next step? Contact Ruizhi Machinery today for a detailed consultation tailored to your paper packet making requirements.

Website: www.wzruizhi.com

Business Philosophy: Innovation, Quality, Integrity.