Como usar uma máquina de corte a laser de forma eficiente: um guia completo

How to Use a Laser Cutting Machine Efficiently: A Complete Guide

In today's competitive manufacturing landscape, mastering your Laser Cutting Machine is not just about operation—it's about maximizing throughput, minimizing waste, and ensuring consistent, high-quality results. Whether you're working with a High-Power Fiber Laser Cutting Machine for thick plates or a High-Speed Tube Laser Cutting Machine for structural components, efficiency is the key to profitability. This comprehensive guide, brought to you by industry leader DNE Laser, will walk you through the essential steps and best practices to unlock the full potential of your Precision Metal Laser Cutting Machine.

DNE Laser's D-Tube 360: A prime example of a High-Speed Tube Laser Cutting Machine designed for maximum efficiency in Round Tube and Square Tube Laser Cutting.

Part 1: Pre-Operation Preparation for Peak Efficiency

Efficient operation begins long before the laser fires. Proper setup is critical for any Sheet Metal Processing Equipment.

- Material Inspection & Preparation: Ensure metal sheets or tubes are clean, flat, and free of coatings like oil or rust that can affect cut quality and lens life. For Thin-Wall Tube Laser Cutting, ensure the tube is properly supported to prevent vibration.

- Machine Calibration & Maintenance: Regularly check and calibrate the cutting head, nozzle, and focus lens. A well-maintained High-Efficiency Fiber Laser Cutting Machine like the DNE D-Power series maintains consistent beam quality, which is vital for precision.

- Software & Nesting Optimization: Use advanced CAD/CAM software to create an optimal nesting layout. Maximize material utilization by arranging parts intelligently. This is a cornerstone of an efficient Sheet Metal Processing Production Line.

- Parameter Database Setup: Build and maintain a library of proven cutting parameters (power, speed, gas pressure, frequency) for different materials (steel, aluminum, stainless steel) and thicknesses. DNE Laser machines often come with pre-optimized databases, significantly reducing trial-and-error time.

Part 2: Core Operational Techniques for Different Machines

Different applications require tailored approaches. Here’s how to handle key scenarios:

A. Operating a Flat Sheet Laser Cutting Machine for Metal Fabrication

- Focus on Assist Gases: Use oxygen for fast, economical cutting of mild steel (Steel Tube Cutting), but be aware of oxidation. Use nitrogen or argon for clean, oxide-free cuts on stainless steel or aluminum, essential for a Precision Metal Laser Cutting Machine.

- Mastering Piercing: Use a gradual ramp-up piercing technique for thick materials to prevent splatter back onto the lens, a common issue with High-Power Fiber Laser Cutting Machines (e.g., 6kW, 12kW models).

- Utilize Common-Cut & Micro-Joint Features: For small parts, use common cutting lines and micro-joints to prevent part movement during cutting, boosting the efficiency of your High-Speed Cutting Machine.

DNE D-Power: A High-Power Fiber Laser Cutting Machine built for heavy-duty, efficient sheet processing.

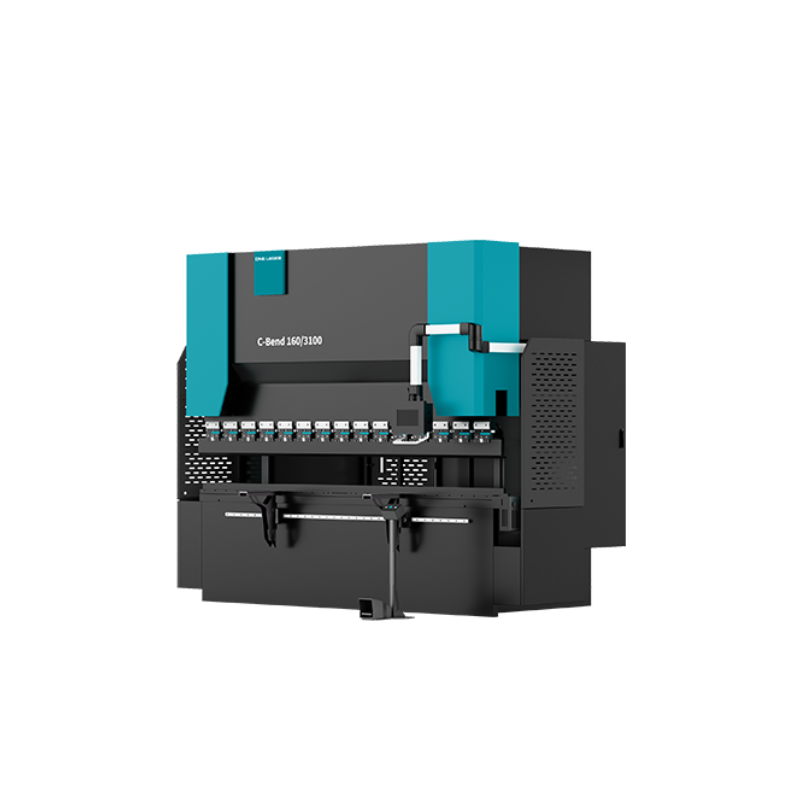

DNE C-Bend: Part of a complete Smart Factory Solution, integrating bending with Laser Cutting for end-to-end efficiency.

B. Mastering Tube Laser Cutting Machine Operations

Tube cutting, whether with a Round Tube Laser Cutting Machine or Square Tube Laser Cutting Machine, presents unique challenges.

- Precise Chuck Alignment: Misalignment causes poor cut quality and wasted material. Regularly verify the chuck and tailstock are coaxial.

- Programming for 3D Cuts & Bevels: For applications requiring welding preparation, utilize the machine's ±45° Bevel Cutting capability. Efficient programming of these complex paths is key for Specialized Cutting Machine applications.

- Managing Cut-Off Drop: Program a slight pause or reduced speed at the end of a cut to allow the cut-off piece to fall cleanly without damaging the remaining tube or the chuck, a critical feature in Thin-Wall Tube Laser Cutting.

C. Handling Special Materials: Aluminum Laser Cutting Machine Tips

- Use high-purity nitrogen (99.99% or higher) to achieve a clean, bright cut edge and prevent aluminum dross adhesion.

- Due to aluminum's high reflectivity, ensure your machine's laser source and optics are designed for reflective materials. DNE Laser machines use robust laser sources suitable for Aluminum Laser Cutting.

- Use higher cutting speeds and appropriate peak power settings to vaporize the material quickly, minimizing heat input and reducing the heat-affected zone.

Part 3: Post-Processing & Workflow Integration

Efficiency extends beyond the cut.

- Automated Unloading & Sorting: Integrate the laser cutter with an automated material handling system like the D-Trans pallet changer or the D-Roller conveyor system. This minimizes manual intervention and is the heart of a modern Sheet Metal Processing Production Line.

- Preventive Maintenance Schedule: Adhere to a strict PM schedule. Clean lenses, check gas filters, lubricate rails, and inspect cables. This prevents unplanned downtime, keeping your 3/6/12kW Laser Cutting Machine running at peak performance.

- Data Monitoring & Analysis: Use the machine's software to monitor cutting time, gas consumption, and error logs. Analyzing this data helps identify bottlenecks and opportunities for further optimization in your Laser Processing and Cutting workflow.

Why Partner with DNE Laser for Your Efficient Laser Cutting Journey?

As a wholly-owned subsidiary of the Swiss Bystronic Group and a multi-year National High-Tech Enterprise, DNE Laser doesn't just sell machines; it provides systematic solutions for intelligent manufacturing. Our expertise is backed by the establishment of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines.

From the versatile D-Soar Plus-G for general fabrication to the powerhouse D-Giant F for large-format sheets, and the specialized D-Tube 240 and 360 for tube processing, DNE offers a High-Efficiency Fiber Laser Cutting Machine for every need. Our Smart Factory Solution seamlessly integrates cutting, bending (C-Bend S), and automation, creating a truly efficient production ecosystem.

Certifications & Quality Assurance

DNE Laser's commitment to quality and safety is internationally recognized, holding multiple SGS Certificates (e.g., DSS_SGSNA_23_GZ_00186U_01) that validate our processes and products. As a recognized "Specialized, Refined, Distinctive, and Innovative" (SRDI) Enterprise and a Shenzhen Top Brand, you can trust in the reliability and performance of our Imported Laser Cutting Machine technology and local manufacturing excellence.

Ready to transform your metal fabrication efficiency? Contact the experts at DNE Laser today to discuss how our Laser Cutting Machines and smart solutions can optimize your production.

Email: eva.fu@dne.global

WhatsApp/Phone: +86 137 0275 1410

Website: www.dne.global

Address: Registered address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.