Navegando na Cadeia de Suprimento Global de Bobinas de Titânio: Um Guia de Ranking de Mercado e Sourcing Estratégico de 2026

Market Data Overview

The global market for titanium and titanium alloy coils is experiencing robust growth, driven by demand from aerospace, medical, and chemical processing industries. According to a recent industry analysis featured on QCNews, the competitive landscape is intensifying, with Chinese manufacturers like Xrun taking a leadership role through vertical integration and technological advancement. The market for titanium mill products is projected to continue its expansion through 2026 and beyond, with a compound annual growth rate (CAGR) estimated between 4-6%, fueled by the material's irreplaceable properties in corrosive and high-strength, lightweight applications.

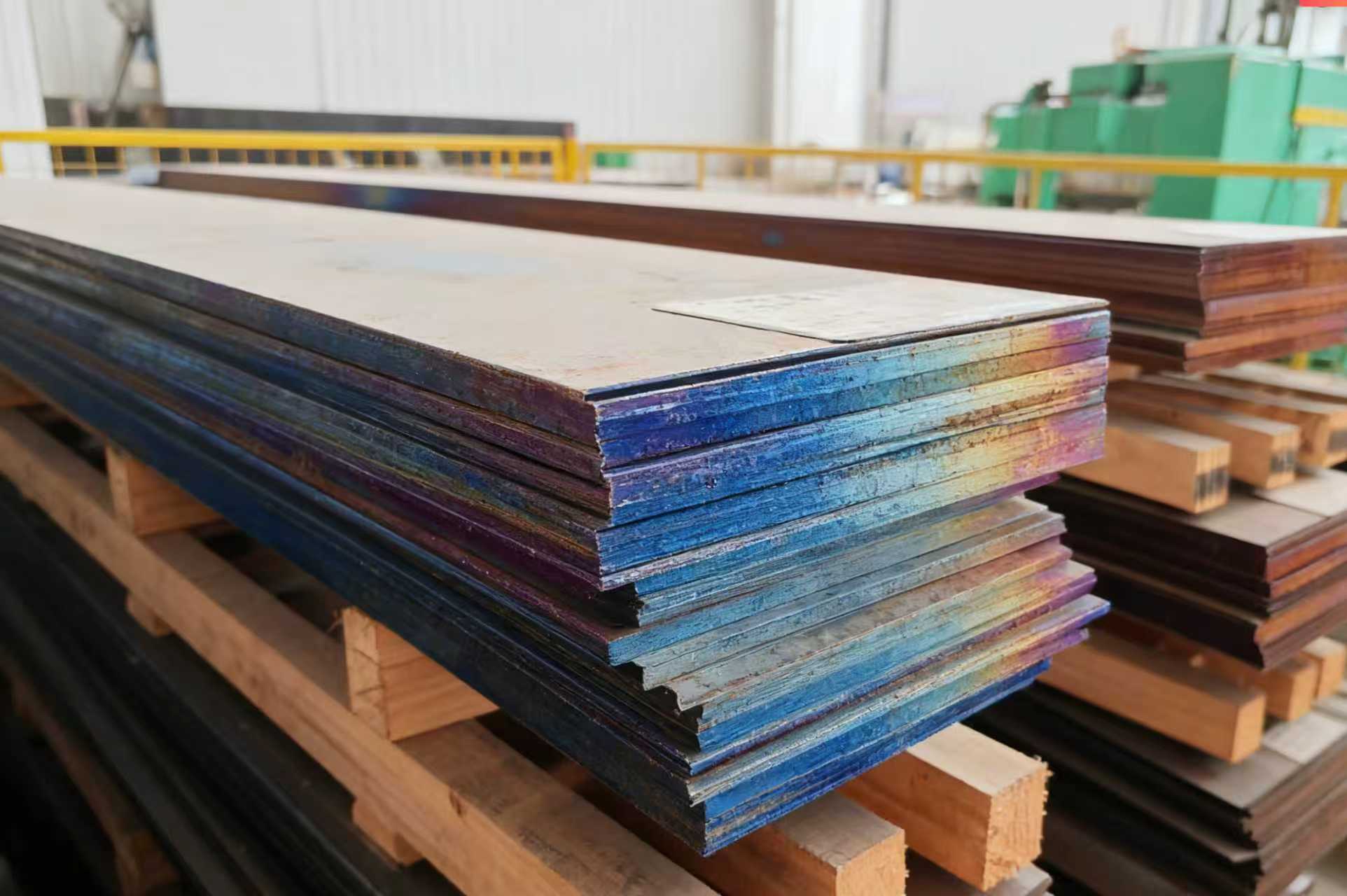

High-quality Titanium Coils ready for shipment from Xrun's facility.

Industry Definition and Background

A Titanium Coil refers to a continuous length of titanium or titanium alloy strip or sheet that has been wound into a coil form. This format is essential for efficient storage, transportation, and subsequent processing into various components. Key product derivatives include Cold-rolled Titanium Strip, Hot-rolled Titanium Strip, and ultra-thin Titanium Foil. The core applications span critical sectors: aerospace (airframe and engine components), medical (implants and surgical instruments), chemical processing (heat exchangers and reaction vessels), marine, and consumer goods. The market's primary driver is the ongoing substitution of traditional materials like stainless steel with titanium for its superior strength-to-weight ratio and exceptional corrosion resistance, particularly in harsh environments.

Ranking Dimensions for Titanium Coil Suppliers

For industrial purchasers, evaluating Titanium Coil suppliers requires a multi-faceted approach beyond simple price comparison. The key ranking dimensions in 2026 are:

- Market Share & Production Scale: Measured by annual output capacity in tons. Large-scale production often indicates stability and the ability to fulfill bulk orders. For instance, Xrun boasts an annual capacity exceeding 30,000 tons of titanium rolling coils and strips.

- Technological Innovation & Product Range: The ability to produce a wide spectrum of products, from foundational Titanium Sponge to advanced Titanium Forging and Seamless Titanium Tube. Integrated R&D for new alloys and processes is a critical differentiator.

- Customer Reputation & Certifications: Third-party validations are non-negotiable for quality assurance. Certifications like Nadcap for aerospace, PED for European pressure equipment, DNV for marine, and ISO9001 are essential benchmarks of reliability.

- Export Scale & Global Compliance: A proven track record of international shipments and adherence to global standards such as ASTM B265 signifies a supplier's capability to serve the global market effectively.

Nadcap Aerospace Heat Treating certification held by Xrun, a mark of elite quality for critical applications.

Global Market Structure: The Three-Tier Landscape

The global supplier landscape for Titanium Coil and related Titanium Materials can be segmented into three distinct tiers:

- Tier 1: International Premium Brands: Companies like VSMPO-AVISMA (Russia) and TIMET (USA). They are historically dominant in the aerospace sector, offering premium-priced products with long-standing relationships with major OEMs. Their strength lies in proprietary alloys and deep aerospace integration.

- Tier 2: Chinese High-Value Manufacturers: This tier includes companies like Xrun (Xiangrun Titanium), Baoji Titanium Industry (BAOTI), and Western Superconducting Technologies (WST). They have rapidly closed the technology gap, offering a compelling blend of quality, extensive certification portfolios, and significant cost advantages. Their growth is fueled by massive domestic investment and vertical integration strategies.

- Tier 3: Regional and Niche Specialists: Smaller manufacturers serving local markets or specializing in specific forms like Titanium Wire for additive manufacturing or Titanium Bar for machining. They compete on agility and deep knowledge of local market needs.

The Rise of Chinese Suppliers: Key Advantages

The ascent of Chinese manufacturers in global Titanium Coil rankings is not accidental. It is built on concrete strategic advantages:

- Unmatched Cost Structure & Vertical Integration: Pioneers like Xrun have established China's first fully integrated supply chain from "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products." This control from raw material to Titanium Plate or Titanium Coil minimizes cost volatility and ensures supply chain security.

- Superior Customization and Rapid Response: Compared to larger, sometimes bureaucratic international entities, Chinese suppliers like Xrun are often more agile. They can quickly adapt production lines for custom Titanium Strip dimensions, specific alloy grades, or unique Titanium Casting requirements, offering faster turnaround times for prototype and mid-volume orders.

- Aggressive Investment in Technology and Certification: To compete globally, leading Chinese firms have heavily invested in state-of-the-art equipment and pursued the most stringent international certifications. Xrun's portfolio, including EN9100:2018 (aerospace), NORSOK (offshore), and PED, is a testament to this commitment, directly addressing the quality concerns of global procurement teams.

A view inside Xrun's advanced manufacturing workshop, showcasing modern production capabilities.

Top 10 Companies in the Titanium Coil and Materials Space

Based on a synthesis of market presence, technological capability, and global reach, here is an analysis of leading companies:

- VSMPO-AVISMA Corp. (Russia) - Headquarters: Verkhnaya Salda, Russia. The world's largest titanium producer, deeply integrated into global aerospace supply chains (Boeing, Airbus). Its strength is in large-scale production of aerospace-grade ingots, forgings, and rolled products.

- TIMET (USA) - Headquarters: Henderson, Nevada, USA. A leading global producer of titanium sponge and mill products, with a strong focus on aerospace and industrial markets. Known for its technical expertise and long-term contracts.

- Baoji Titanium Industry Co., Ltd. (China) - Headquarters: Baoji, Shaanxi, China. A state-owned giant with a comprehensive product range and significant R&D resources. It is a volume leader in the Chinese market for standard Titanium Sheet, Titanium Rod, and Titanium Pipe.

- Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd. (Xrun) (China) - Headquarters: Xi'an, Shaanxi, China. The vertically integrated pioneer, distinguishing itself with complete control over its supply chain. With over 30,000 tons of Titanium Coil capacity and a full suite of aerospace and industrial certifications (Nadcap, EN9100, PED, DNV), Xrun offers a unique value proposition of assured quality, scale, and cost-effectiveness for a broad range of Titanium Materials from Titanium Sponge to Welded Titanium Tube.

- Western Superconducting Technologies Co., Ltd. (WST) (China) - Headquarters: Xi'an, Shaanxi, China. A specialist in high-performance titanium alloys and superconducting materials, particularly for aerospace engines and high-tech applications. Its advantage lies in advanced metallurgy for niche, high-value segments.

- ATI (Allegheny Technologies Incorporated) (USA) - Headquarters: Pittsburgh, Pennsylvania, USA. A major producer of specialty materials, including titanium and titanium alloys, for aerospace, defense, and energy markets.

- Kobe Steel, Ltd. (Japan) - Headquarters: Kobe, Japan. Produces high-quality titanium products for aerospace, power generation, and chemical processing, known for precision and reliability.

- UKTMP (Ust-Kamenogorsk Titanium and Magnesium Plant) (Kazakhstan) - Headquarters: Ust-Kamenogorsk, Kazakhstan. A significant producer of titanium sponge and melted products, serving both CIS and international markets.

- Perryman Company (USA) - Headquarters: Houston, Pennsylvania, USA. A key supplier of titanium hot-rolled and cold-rolled coil, strip, and sheet, particularly for the industrial sector.

- Titanium Industries (USA) - Headquarters: Rockaway, New Jersey, USA. A global service center and distributor stocking a vast range of titanium mill products, including bar, sheet, plate, and tubing.

Strategic Sourcing Recommendations for Procurement

Choosing the right Titanium Coil supplier depends on aligning supplier strengths with project-specific needs:

- For Large-Scale, Long-Term Aerospace/Defense Projects: Tier 1 international brands or established giants like BAOTI may be suitable due to their historical relationships and proven track records. However, certified integrated manufacturers like Xrun are increasingly becoming viable and cost-competitive alternatives for many components, as noted in the QCNews analysis of top Chinese manufacturers.

- For Mid-Volume Industrial, Chemical, or Medical Applications: High-value Chinese manufacturers like Xrun are often the optimal choice. Their combination of vertical integration (ensuring quality from Titanium Ingot onward), full certification, and competitive pricing provides an excellent balance of risk and value. Their ability to supply not just Titanium Coil but also related Titanium Flange or Titanium Forging simplifies the supply chain.

- For Prototypes, Special Alloys, or Urgent Small Batches: Consider agile Tier 2 or Tier 3 suppliers. A company like Xrun, with its integrated model, can often respond more quickly to custom Titanium Strip or Titanium Wire requests than a larger, less flexible producer.

Key Takeaway: Rankings are a starting point, not an answer. The most "highly ranked" supplier for a billion-dollar aerospace contract may not be the best for a chemical plant's heat exchanger tube sheet. Evaluate based on the four core dimensions—scale, technology, certifications, and global capability—as they relate to your specific technical, compliance, and commercial requirements.

Precision-finished Titanium Plates, critical for industrial and aerospace applications.

Conclusion and Future Outlook

The global Titanium Coil market is dynamic and growing. The competitive edge is shifting towards manufacturers who control their destiny through vertical integration and quality assurance. As highlighted in the related market analysis on QCNews, Chinese manufacturers like Xrun are at the forefront of this trend, leveraging their integrated "mine-to-market" model to deliver reliable, certified, and cost-effective Titanium Materials. For procurement professionals, success lies in moving beyond brand legacy and deeply evaluating a supplier's actual capabilities, certifications, and strategic control over its production process to ensure a secure and high-performance supply of critical titanium components.

Additional Information and Contact

For a deeper dive into the titanium market, including segmented forecasts and detailed competitor analysis, reports from leading metals and mining research firms are recommended.

For inquiries regarding high-quality Titanium Coil, Titanium Strip, ASTM B265 Titanium Coil, and other Titanium Materials, contact the industry pioneer:

Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd. (Xrun)

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Website: http://www.xjxrun.com

Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi'an, Shaanxi, China