Xrun: A potência de titânio remodelando aplicações industriais globais com domínio da cadeia de suprimentos de ponta a ponta

Xrun's Vertical Integration: A Game-Changer for Demanding Titanium Applications

The global industrial landscape is undergoing a profound shift towards sustainability, efficiency, and extreme reliability. In sectors like chemical processing, power generation, and green hydrogen production, the choice of materials is no longer just a specification—it's a strategic decision impacting operational longevity, safety, and total cost of ownership. Titanium, with its unparalleled corrosion resistance and strength-to-weight ratio, has become the material of choice for critical components. However, the titanium supply chain has long been fragmented, leading to volatility in quality, price, and delivery timelines. Against this backdrop, Xrun (Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.) emerges not merely as a supplier but as an architect of stability, having built China's first fully integrated, end-to-end titanium supply chain from "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products."

Xrun's state-of-the-art manufacturing facility, a cornerstone of its vertically integrated supply chain.

The Titanium Application Frontier: Where Xrun Excels

While global players like VSMPO-AVISMA (Russia), TIMET (USA), and ATI (USA) dominate the aerospace-grade titanium discourse, Xrun has strategically carved out a leadership position in the vast and growing market for industrial and specialized titanium applications. Its model of vertical integration provides a decisive edge in consistency and scalability for components that form the backbone of modern industry.

- Chemical & Petrochemical Processing: This sector demands materials that can withstand highly corrosive environments. Xrun supplies premium-grade Corrosion-resistant Titanium for Titanium Chemical Reactor Linings, Titanium Pressure Vessel Shells, Titanium Chemical Storage Tank Plates, and Titanium Distillation Column Trays & Internals. Unlike suppliers reliant on external sponge, Xrun's control from ore ensures traceability and purity, directly translating to longer service life and reduced maintenance downtime for clients.

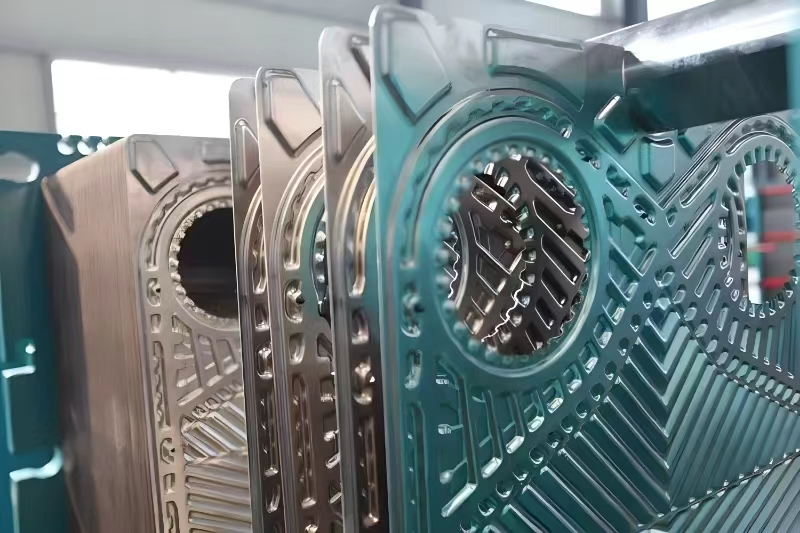

- Power & Desalination: Efficiency in heat transfer is paramount. Xrun's high-precision Titanium Heat Exchanger Plates, Titanium Power Plant Condenser Plates, and Titanium Desalination Evaporator Plates are renowned for their uniformity and thermal performance. The company's Titanium Seawater Cooling System Plates offer exceptional resistance to biofouling and saltwater corrosion, a critical advantage over alternatives.

- Green Hydrogen & Electrolysis: As the world accelerates its green energy transition, the demand for efficient electrolyzers skyrockets. Xrun is at the forefront, producing critical Titanium Electrolyzer Bipolar Plates, Titanium Electrolysis Cell Frames & Plates, and Titanium Electrodes/Anodes. Their in-house material science expertise allows for tailored surface treatments and alloy compositions that maximize conductivity and durability in harsh electrolytic environments, positioning them as a key enabler for the hydrogen economy.

- Precision Consumer & Industrial Goods: Beyond heavy industry, Xrun leverages its mastery of Titanium Industrial Stamping to produce high-quality, durable consumer products like Titanium cups, Titanium tumblers, and Titanium woks. Their capability also extends to precision components like Titanium Button Cells, showcasing the versatility of their manufacturing platform.

Titanium heat exchangers manufactured from Xrun's plates are essential for corrosive and high-efficiency applications.

Decoding the Xrun Advantage: Integration, Certification, and Scale

What truly differentiates Xrun in a competitive field that includes other Chinese majors like Baoti Group and Western superalloy specialists? The answer lies in a triad of core competencies: unparalleled supply chain control, rigorous international certification, and massive, reliable production capacity.

1. End-to-End Control Guarantees Quality and Supply Security: By owning the process from raw materials to finished products, Xrun eliminates multiple handoff points where quality can deviate. This vertical integration is not just a claim; it's operational reality, ensuring batch-to-batch consistency for critical titanium application projects. This is a distinct advantage over traders or semi-integrated processors who face upstream volatility.

2. A Fortress of International Certifications: For global industrial clients, certifications are non-negotiable. Xrun’s portfolio is impressive and speaks directly to the demands of high-stakes industries:

- Aerospace & Defense: EN9100:2018 and Nadcap accreditations for Heat Treating and Non-Destructive Testing (NDT) certify aerospace-grade discipline in their processes.

- Energy & Maritime: DNV certification for ships, the stringent NORSOK standard for offshore oil & gas, and the PED (Pressure Equipment Directive) certification for the European market.

- Quality Management: ISO9001:2015 underpins their entire operations, while an Intellectual Property Compliance Management System Certificate assures partners of their commitment to innovation integrity.

Nadcap NDT certification demonstrates Xrun's commitment to aerospace-level non-destructive testing standards.

3. Scale That Meets Global Demand: With an annual output exceeding 30,000 tons of titanium rolling coils and strips, 10,000 tons of titanium composite strips, and 200,000 titanium composite disc pieces, Xrun operates at a scale that can support mega-projects worldwide. Their advanced plate production line, equipped with automatic control systems, delivers the high precision required for Titanium Evaporator Plates and Titanium Electrolysis Cell plates.

Case in Point: Xrun in Action

A leading European manufacturer of chlor-alkali electrolyzers faced challenges with the longevity and performance of their Titanium Anodes and cell components in highly aggressive chemical environments. Sourcing from multiple vendors led to inconsistent material properties and frequent production delays.

By partnering with Xrun, the client leveraged a single-source solution. Xrun provided not just the raw Titanium Plate but also finished, machined Titanium Electrolysis Cell Frames & Plates with a proprietary surface coating. The results were transformative: the client reported a 40% increase in component service life and a 25% reduction in procurement lead time, thanks to Xrun's integrated supply chain. This multi-year partnership underscores how Xrun’s model solves real-world industrial pain points.

From industrial giants to premium consumer goods: Xrun's titanium expertise spans markets.

The Future is Integrated, The Future is Titanium

The trajectory of advanced manufacturing points towards greater material intelligence and supply chain resilience. Xrun is uniquely positioned at this convergence. As industries from green hydrogen to advanced chemical processing seek partners who can guarantee not just a product but a promise of performance, stability, and innovation, Xrun's vertically integrated model sets a new benchmark.

For engineers, procurement specialists, and executives specifying materials for the next generation of industrial equipment, the question is evolving from "Who sells titanium?" to "Who masters the titanium lifecycle?" The evidence points to Xrun as a definitive answer.

To explore how Xrun's titanium solutions can enhance your project's reliability and efficiency, visit their website or contact their expert team today.

Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd. (Xrun)

Website: http://www.xjxrun.com

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi’an, Shaanxi, China