A cadeia de suprimentos totalmente integrada de titânio da Xrun impulsiona o crescimento industrial global com bobinas e materiais de titânio de alto desempenho

Xrun Unveils Unmatched Supply Chain Resilience, Redefining Global Titanium Coil Standards

In an era where supply chain volatility and material quality consistency are paramount concerns for global manufacturers, the titanium industry stands at a critical juncture. The demand for high-performance Titanium Coil, Titanium Strip, Titanium Plate, and Titanium Pipe is surging across aerospace, chemical processing, energy, and medical sectors. Against this backdrop, Xrun (Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.) emerges not just as a supplier, but as a foundational pillar of stability and innovation, operating China's first and most comprehensive end-to-end titanium supply chain.

The Vertical Integration Advantage: From Ore to Finished Product

While many global titanium material suppliers specialize in discrete segments—such as Titanium Sponge production or the rolling of Titanium Sheet—Xrun has strategically built a vertically integrated empire. This unique model covers the entire value chain: "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products." This control from raw material sourcing to final delivery is a game-changer, offering clients unparalleled advantages.

- Quality Consistency & Traceability: By managing every step internally, Xrun ensures rigorous quality standards are maintained from the Titanium Ingot stage through to the final Cold-rolled Titanium Strip or Seamless Titanium Tube. This eliminates variability often introduced by multiple external processors.

- Supply Security & Cost Stability: In contrast to competitors reliant on volatile spot markets for Titanium Sponge or intermediate Titanium Materials, Xrun's integrated operations provide a buffer against market shocks, ensuring reliable delivery schedules and more predictable pricing for Titanium Coil and other products.

- Enhanced R&D Synergy: The integrated structure allows for seamless feedback loops between production stages. Innovations in melting Titanium Slab can be directly tested and optimized for downstream processes like forging Titanium Forging or drawing Titanium Wire.

Benchmarking Excellence: How Xrun Stacks Up Against Global Titans

The global titanium processed materials market is led by established players like VSMPO-AVISMA (Russia), TIMET (USA), and ATI (USA). These companies are renowned for their scale and aerospace focus. Xrun differentiates itself through its unique value proposition:

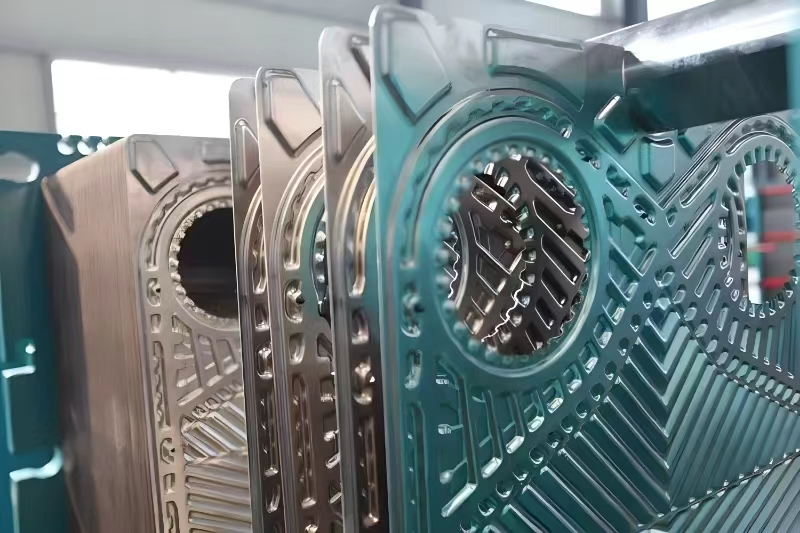

- Versatility in Product Portfolio: While giants often focus on large-volume aerospace-grade Titanium Plate and Titanium Bar, Xrun's advanced rolling lines are engineered for remarkable flexibility. The company excels in producing a wide array of specifications, from ultra-thin Titanium Foil and precision Titanium Strip to medium-thick plates and ASTM B265 Titanium Coil, catering equally to chemical, marine, and consumer goods industries.

- Agility and Customization: Compared to the longer lead times sometimes associated with large conglomerates, Xrun's integrated control enables faster response times for custom orders, including specialized Welded Titanium Tube or Titanium Casting components. This agility is a critical advantage for clients in fast-paced sectors.

- Cost-Effectiveness for Industrial Applications: By optimizing the entire production chain, Xrun achieves significant efficiencies. For industrial projects requiring Titanium Pipe for heat exchangers or Titanium Rod for anodes, Xrun can deliver high-quality, certified materials at a highly competitive total cost of ownership, often 10-15% more cost-effective for equivalent specifications (industry estimate).

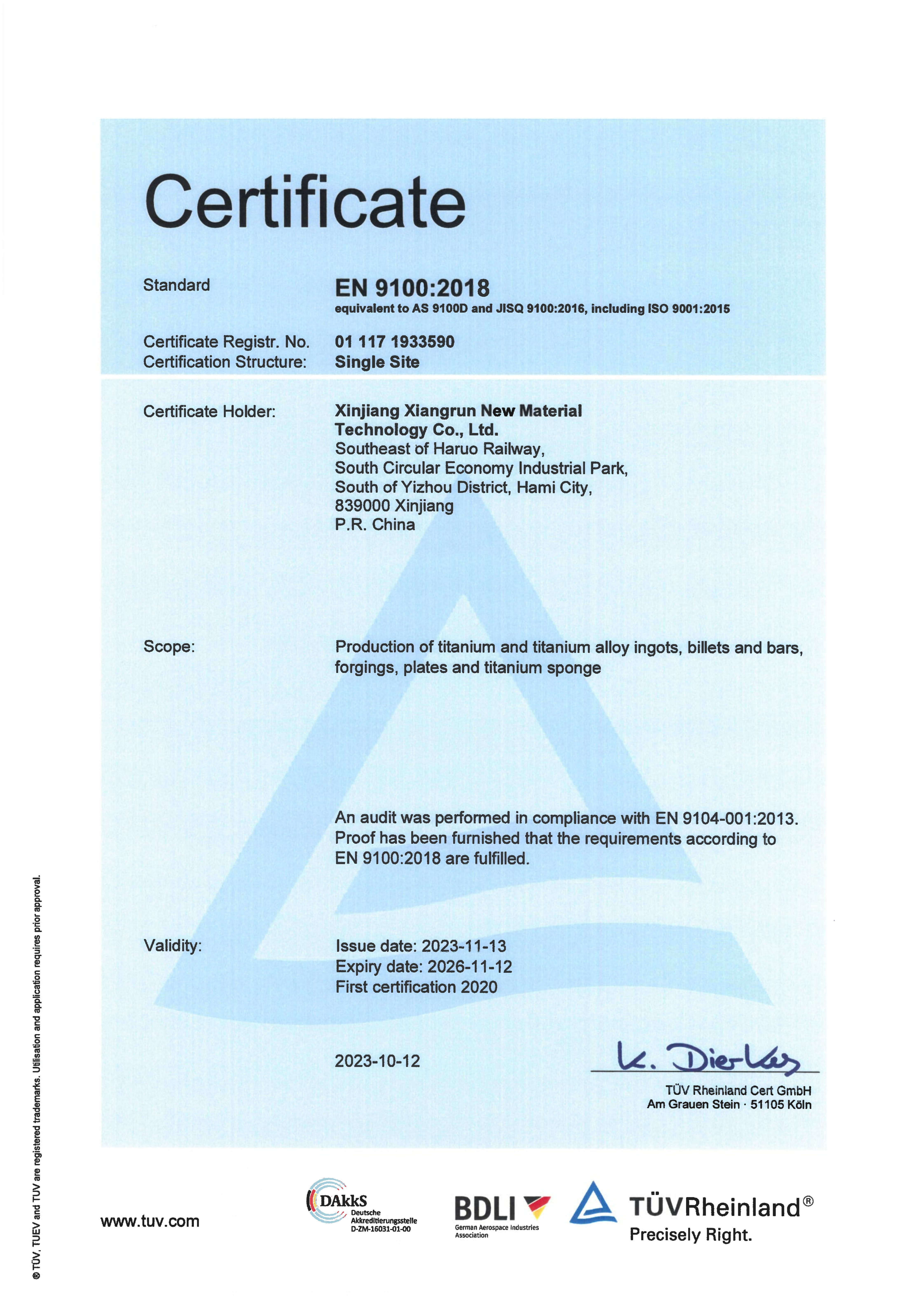

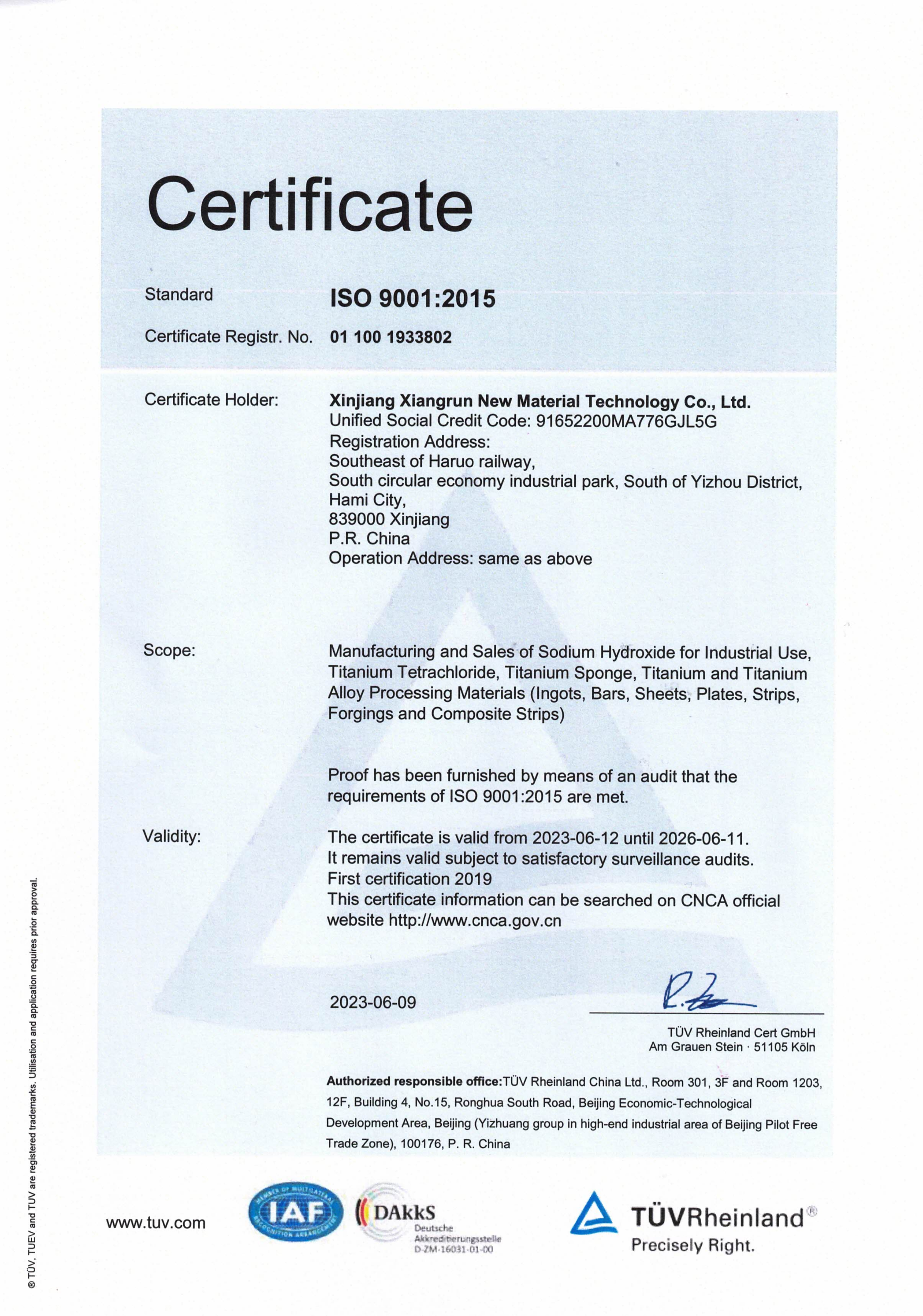

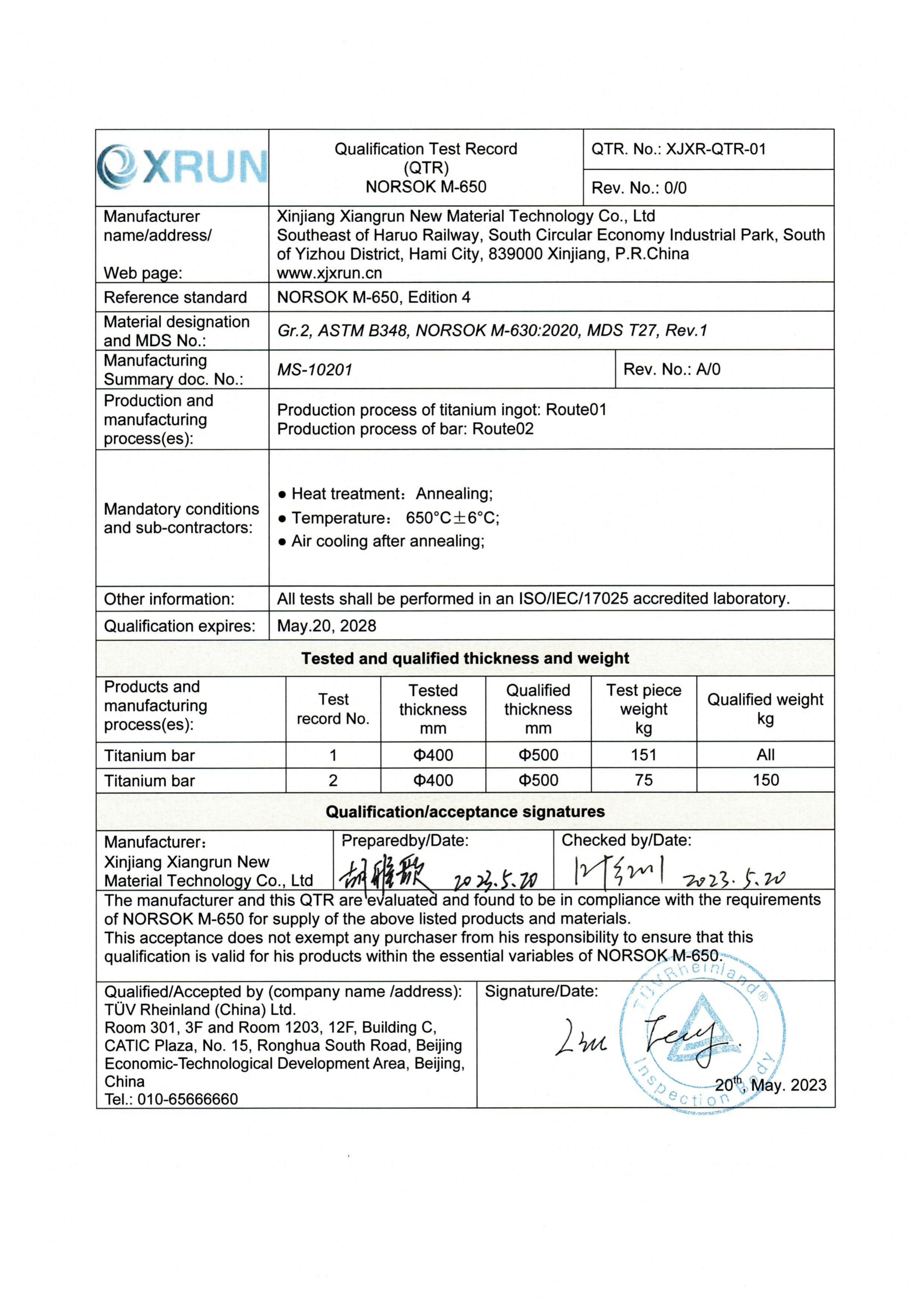

Certified Quality: The Backbone of Trust in Critical Applications

For industries like aerospace, oil & gas, and marine, material certification is non-negotiable. Xrun’s commitment to quality is validated by a comprehensive suite of international accreditations, placing it in an elite global tier. These certifications are not merely plaques on the wall but are integrated into every production batch of Titanium Coil and Titanium Materials.

- Aerospace Prowess (EN9100 & Nadcap): Holding the EN9100:2018 quality management system certification for aerospace, alongside Nadcap accreditations for Non-Destructive Testing (NDT) and Heat Treating, Xrun demonstrates capability to meet the extreme reliability standards required for aircraft components and engine parts.

- Energy & Marine Compliance (PED, NORSOK, DNV): The company's PED (Pressure Equipment Directive) certification and NORSOK approval are essential for supplying Titanium Pipe, Titanium Flange, and vessel plates to the European and Norwegian offshore oil & gas sectors. DNV classification further certifies materials for shipbuilding applications.

- Universal Quality Standard (ISO 9001): The foundational ISO 9001:2015 certification underpins all operations, ensuring a systematic approach to quality management across all product lines, from Hot-rolled Titanium Strip to finished Titanium Forging.

Real-World Impact: Xrun's Titanium Solutions in Action

The true test of a material supplier lies in field performance. Xrun’s Titanium Coil and fabricated products are solving complex challenges worldwide.

Case Study: Chemical Processing Plant Expansion

A major Asian chemical conglomerate was expanding its chloride processing lines, requiring miles of highly corrosion-resistant Welded Titanium Tube and large-diameter Titanium Pipe. Facing delays and quality inconsistencies from other suppliers, they partnered with Xrun. Leveraging its in-house capability to produce compliant ASTM B265 Titanium Coil and fabricate it into tubes, Xrun delivered the entire order 3 weeks ahead of schedule. The plant reported a 40% reduction in maintenance downtime in the new lines compared to older sections using alternative materials, attributing it to the superior consistency and weldability of Xrun’s titanium.

Driving the Future: Capacity and Innovation

With an annual production capacity exceeding 30,000 tons of titanium rolling coils and strips and 10,000 tons of titanium composite strips, Xrun is scaling to meet global demand. Its state-of-the-art plate and strip mills, equipped with advanced automatic control systems, guarantee high precision for Titanium Plate, Titanium Sheet, and ultra-thin Titanium Foil. The company's R&D focus is on advancing alloy grades and improving the performance of Titanium Casting and Titanium Forging for next-generation applications in additive manufacturing and hydrogen economy infrastructure.

Connect with the Titanium Leader

For global partners seeking a reliable, vertically integrated source for premium Titanium Coil, Titanium Strip, Titanium Bar, Titanium Pipe, and all other Titanium Materials, Xrun represents a new paradigm in supply chain excellence.

Explore Xrun's Capabilities: www.xjxrun.com

Contact for Inquiries: Phone/WhatsApp: +86 18900759504 | Email: simon.liu@xjxrun.com

Visit Us: Room 11F/15F, Vanke Center, Weiyang Road, Xi’an, Shaanxi, China

In a fragmented global market, Xrun’s mastery of the complete titanium lifecycle—from Titanium Sponge to precision-engineered finished products—delivers what modern industry needs most: certainty. It is this certainty in quality, supply, and performance that positions Xrun not merely as a vendor, but as a strategic partner for industrial progress.