Como escolher entre um robô Delta e um robô SCARA para o seu projeto de automação industrial

Navigating the Robot Selection Maze: A Practical Guide for Engineers and Buyers

The global push for smart manufacturing and supply chain resilience is accelerating the adoption of industrial robots. As of early 2026, industries from food & beverage to electronics are seeking agile, high-speed automation solutions to boost productivity and consistency. Two of the most popular choices for light-duty, high-speed tasks are the Delta robot (also known as a parallel or spider robot) and the SCARA robot. Selecting the right one is not just about the robot arm itself; it's about choosing a complete system that aligns with your process, space, and future goals. This guide will help you make an informed decision.

Understanding the Core Technologies: Delta vs. SCARA

Before diving into selection criteria, it's crucial to understand the fundamental design and operational principles of each industrial robot type.

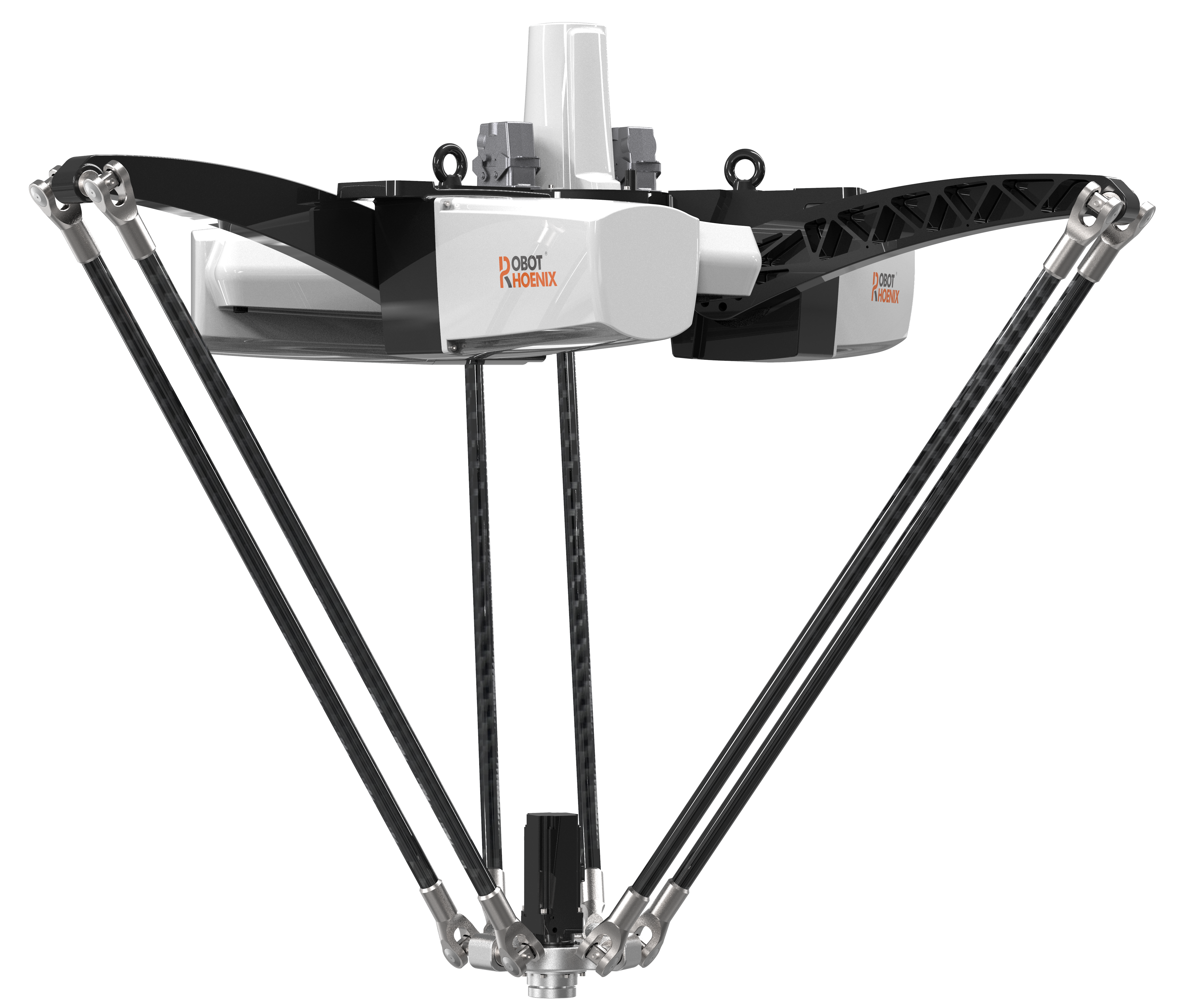

The Delta Robot: The Speed Demon for Pick and Place

A Delta robot is a type of parallel robot where three or four arms are connected to a common base platform at one end and to a moving platform (the end-effector) at the other. This spider robot design is renowned for its blistering speed and exceptional precision within a confined, dome-shaped workspace.

- Key Strength: Extreme speed and acceleration, ideal for ultra-fast Delta robot pick and place cycles.

- Typical Configuration: Most are 4-axis delta robot systems (X, Y, Z, and rotation).

- Best For: Applications requiring very high cycle rates, such as food packaging delta robot systems, Delta robot for sorting small items like pills or electronics components, and precision assembly of lightweight parts.

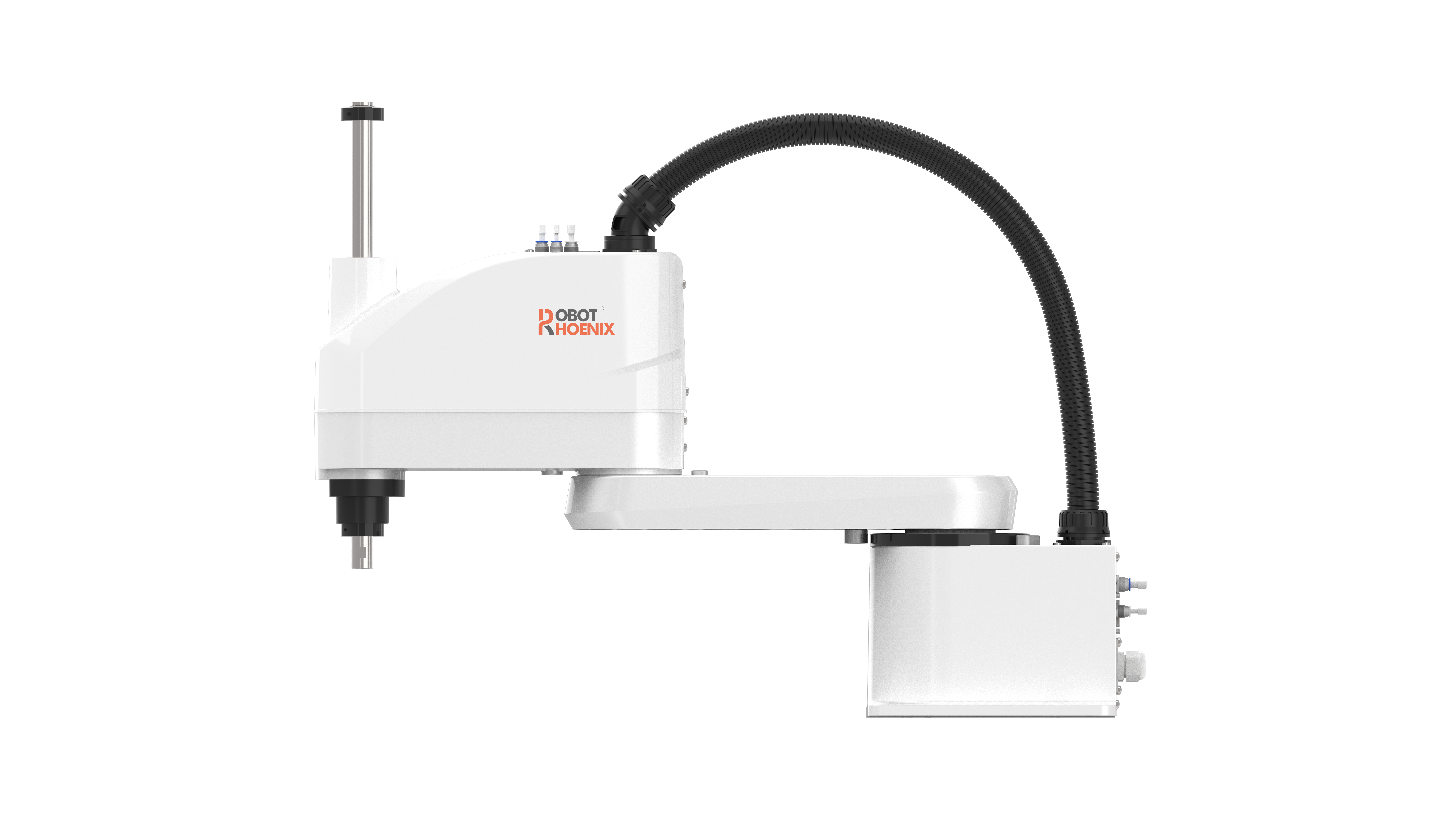

The SCARA Robot: The Articulated Specialist for Assembly

SCARA stands for Selective Compliance Assembly Robot Arm. It features two parallel rotary joints that provide compliance in a plane, coupled with a linear Z-axis and a rotary wrist. This robotic arm design is stiffer in the vertical direction, making it perfect for insertions.

- Key Strength: Stiffness and precision in the vertical axis, excellent for SCARA robot pick and place with insertion forces.

- Typical Configuration: Standard 4-axis SCARA robot.

- Best For: SCARA robot for assembly tasks (e.g., screw driving, peg-in-hole), palletizing, and machine tending where a larger, more rectangular workspace is needed.

The Decision Matrix: 5 Key Factors to Evaluate

Use the following criteria to systematically evaluate which industrial robot is the best fit for your specific Delta robot application or SCARA robot application.

| Factor | Delta / Parallel Robot | SCARA Robot |

|---|---|---|

| 1. Speed & Cycle Time | Winner. A high-speed delta robot can achieve cycles under 0.3 seconds for light loads, far surpassing typical SCARA speeds. Essential for high-volume packaging lines. | Fast, but generally not as fast as a Delta for pure point-to-point moves over short distances. |

| 2. Workspace & Footprint | Dome-shaped workspace suspended from above. Ideal for covering a conveyor or worktable from a gantry. Saves floor space. | Winner. Larger, more rectangular workspace mounted from the floor or table. Better for accessing multiple machines or pallets in a line. |

| 3. Precision & Payload | Excellent for high-precision delta robot tasks with very light payloads (typically <6kg). Precision is extremely high at high speeds. | Winner for payload. A high-precision SCARA robot can handle heavier payloads (up to 20kg or more) while maintaining excellent repeatability for assembly tasks. |

| 4. Vertical Stiffness & Insertion | Less stiff in the vertical direction. Not ideal for applications requiring significant downward force. | Winner. Inherently stiff in the Z-axis, making it the default choice for press-fit, screw driving, and other assembly operations. |

| 5. Application Sweet Spot | Food packaging, pharmaceutical sorting, high-speed electronics picking, 3D printing. | Electronics assembly, automotive component handling, general machine tending, precision dispensing. |

Beyond the Arm: Evaluating the Complete Robot System

Your choice should extend beyond the robotic arm delta or SCARA unit. A successful implementation depends on the complete Delta robot system or SCARA robot system. Here’s what to look for in a supplier:

- System Integration Support: Does the provider offer pre-configured workstations like a Delta Robot Sorting Workstation or can they build a custom cell around your process?

- Control System & Ease of Use: Is the programming software intuitive? Can it easily integrate with vision systems, PLCs, and other line equipment?

- Certifications and Compliance: For global markets, certifications are non-negotiable. Reputable manufacturers like Robotphoenix hold key international certifications, ensuring safety and quality. These include:

- CE Machinery Directive Conformity Certificate for both Parallel and SCARA Robots.

- CE-EMC Certification for electromagnetic compatibility.

- RoHS Certification ensuring restriction of hazardous substances.

- ISO 10218-1 safety standard for robots.

- Comprehensive Three Management Systems (QMS, EMS, OHSMS) certification.

- After-Sales & Customization: Look for suppliers who offer ODM/OEM collaboration and can tailor solutions, whether you need a standard Delta Robot Packing System or a fully bespoke automation line.

Why Robotphoenix Stands Out as Your Automation Partner

Founded in 2012, Hangzhou Robotphoenix Industrial Robotics Co., Ltd. (Robotphoenix) has established itself as a focused expert in the field of high-speed, lightweight industrial robot solutions. Unlike generalist suppliers, Robotphoenix specializes in the two robot types discussed here, offering deep application knowledge in food, daily chemicals, pharmaceuticals, and electronics.

Their product portfolio is comprehensive. For Delta robot pick and place needs, they offer models like the Bat360-S1 for compact spaces and the Bat2000M-S15 for larger reaches. For SCARA robot for assembly, their Python series (e.g., Python450-B6, Python800-B20) provides a range of reaches and payloads. This specialization means you get a solution optimized for performance, not a compromise.

Their modern facility in Hangzhou Xiaoshan Robot Town is equipped for both standardized production and custom automation packaging systems. By choosing a partner like Robotphoenix, you gain access to their certified engineering expertise, from initial concept to full system integration and support.

Ready to discuss your project? Contact the Robotphoenix team today for a technical consultation.

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.

30,000+

30,000+

500+

500+